Why?Really dangerous idea

-

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

A Frame Crane(s)?

- Thread starter 74M35A2

- Start date

More options

Who Replied?- 888

- 9

- 0

- Location

- Seattle, WA

I don't imagine it would do you much good, but I have a complete military A Frame Kit for a little truck (M-37). It is basically the same as the illustrations that Clinto posted.

I could take photos (close ups) of the pole ends or whatever else you would like to see, if needed.

Storm 51

I could take photos (close ups) of the pole ends or whatever else you would like to see, if needed.

Storm 51

- 1,672

- 897

- 113

- Location

- Central NY

RE A-Frame mounting alone;

I wonder if you could mount the A-Frame poles at the bottom

and use the top for support chains and eliminate that pita cable

over the top to the rear?

Really dangerous idea

Look at the leverage the length of the A frame puts on the tether that would go over the cab - it would be similar to the load being lifted - approximately similar angles. Now look at the magnification of torque put on anchors that are only a bumper height above the pivot - upwards of many tens of times the load if not hundreds, like trying to use a pry bar the other way round - pushing on the chisel point to raise the handle, pivoting on the heel of the chisel point. What you'd end up doing is shearing off the top shackle bolts with minimal load and the whole lot would come crashing down in a hurry.Why?

Keep with the over the cab tether idea. Can put "goal post" behind cab to move tether up and off of roof.

Could even double up the front wheels, like rear duals, for tire capacity and allow you to travel a bit (hard steering) with suspension blocked of course.

Last edited:

- 4,030

- 3,471

- 113

- Location

- Peoria, Illinois

Darn science and math,,,,,,Look at the leverage the length of the A frame puts on the tether that would go over the cab - it would be similar to the load being lifted - approximately similar angles. Now look at the magnification of torque put on anchors that are only a bumper height above the pivot - upwards of many tens of times the load if not hundreds, like trying to use a pry bar the other way round - pushing on the chisel point to raise the handle, pivoting on the heel of the chisel point. What you'd end up doing is shearing off the top shackle bolts with minimal load and the whole lot would come crashing down in a hurry.

View attachment 600054

Keep with the over the cab tether idea. Can put "goal post" behind cab to move tether up and off of roof.

Could even double up the front wheels, like rear duals, for tire capacity and allow you to travel a bit (hard steering) with suspension blocked of course.

mao!!

mao!!Thanks for the explanation and example, very informative........well done.

- 3,871

- 504

- 83

- Location

- Gray Court SC

You should be able to mount to all 4 shackels.

No different then a 3 point boom pole on the rear of a tractor.

No different then a 3 point boom pole on the rear of a tractor.

gimpyrobb

dumpsterlandingfromorbit!

- 27,791

- 788

- 113

- Location

- Cincy Ohio

The frame of the truck is much less substantial than any crane. I wouldn't do it.

74M35A2

Well-known member

- 4,142

- 340

- 83

- Location

- Livonia, MI

You're no fun. But, when the rear axle of my truck is 8' in the air and most of my diesel fuel is gurgling out the fill cap, I'll crawl back and say you were right.The frame of the truck is much less substantial than any crane. I wouldn't do it.

Yes, too much tension to place the crane boom tie back that close to the boom itself. I bought a second 20k hydro winch to place at the rear of my frame under the bed. Will have a trap door that flips up from the bed floor, and can extend the cable up through the bed, and then over the top of the cab with some sort of guide post, this is still TBD design until I have the winch mounted, but I may do another drop leg for the tire crane and then a sheave on the tire crane horizontal pole, or something like that.

The picture posted was nearly what I had imagined, thanks for posting it. Only difference is to use a single tether cable to the center mounted rear winch, should be OK. Easy to control boom angle then. Only problem to overcome will be when the crane boom poles are initially lying down on the ground, the angle will be steep in a down direction and the tether cable will drag heavily over the cab roof and maybe even the hood edge. It is like I may need a nylon block with a groove cut into it to guide the cable across the cab roof while it has minimal load on it, or something of that nature. The roof structure on the M939's are all but strong...... Just the wind blowing across their top can make them oil-can. Ugh...

Last edited:

quickfarms

Well-known member

- 3,495

- 25

- 48

- Location

- Orange Junction, CA

A pesky thing called work got in the way of me responding quicker. It is funny how you can change the geometry and increase the loads by an incredible factor.Look at the leverage the length of the A frame puts on the tether that would go over the cab - it would be similar to the load being lifted - approximately similar angles. Now look at the magnification of torque put on anchors that are only a bumper height above the pivot - upwards of many tens of times the load if not hundreds, like trying to use a pry bar the other way round - pushing on the chisel point to raise the handle, pivoting on the heel of the chisel point. What you'd end up doing is shearing off the top shackle bolts with minimal load and the whole lot would come crashing down in a hurry.

View attachment 600054

Keep with the over the cab tether idea. Can put "goal post" behind cab to move tether up and off of roof.

Could even double up the front wheels, like rear duals, for tire capacity and allow you to travel a bit (hard steering) with suspension blocked of course.

- 1,672

- 897

- 113

- Location

- Central NY

quickfarms

Well-known member

- 3,495

- 25

- 48

- Location

- Orange Junction, CA

There is a big differenceYou should be able to mount to all 4 shackels.

No different then a 3 point boom pole on the rear of a tractor.

The lift arms are designed for lifting. The three point hitch lift arms ability are limited by the hydraulics of the tractor, they should stop lifting before things really go bad. You will actually lift the front end first and to counter this you add weight to the front end.

The shackle mounts, bumper bolts and frame extensions are not designed for lifting or the extreme torque of this.

- 2,102

- 32

- 38

- Location

- Delta Junction, Alaska

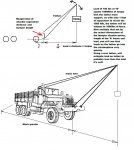

I have an M37 sized boom on my M37, much like the one in the picture, but without the 2nd winch. It has the headache rack - a must have option. It will pick a ton & move with it. 2 tons with jack stands under the bumper. Safe? I don't know, but nothing is safe, unless one uses care. The 1st problem will be that once you have a boom, you will keep using it... so be safe! A couple of points that I will make is that you can raise the boom to the desired angle, if you have a clevis on the corner of the headache rack, thread the winch line through the pulley on top of the boom & then back to the corner of the headache rack. There will be some strain until the boom gets raised a bit, just like on real cranes. I just have a pined plate on the top of the boom that I hang a snatch block in. It is very important to have that hole lined with the center of the axis of the legs of the boom. Otherwise it will induce a "moment" in the boom legs, which can lead to structural failure, in extremes. Yes, the back end can come off the ground. When I was much younger, my response was a 1/2" in the back - its still there, and still running.Some kind of a head ache rack like on a bolster truck might be an option. Make it look like a permanent first hood hoop but stronger?

View attachment 600090

Csm Davis

Well-known member

- 4,169

- 406

- 83

- Location

- Hattiesburg, Mississippi

Hey did you ever finish this?

You're no fun. But, when the rear axle of my truck is 8' in the air and most of my diesel fuel is gurgling out the fill cap, I'll crawl back and say you were right.

Yes, too much tension to place the crane boom tie back that close to the boom itself. I bought a second 20k hydro winch to place at the rear of my frame under the bed. Will have a trap door that flips up from the bed floor, and can extend the cable up through the bed, and then over the top of the cab with some sort of guide post, this is still TBD design until I have the winch mounted, but I may do another drop leg for the tire crane and then a sheave on the tire crane horizontal pole, or something like that.

The picture posted was nearly what I had imagined, thanks for posting it. Only difference is to use a single tether cable to the center mounted rear winch, should be OK. Easy to control boom angle then. Only problem to overcome will be when the crane boom poles are initially lying down on the ground, the angle will be steep in a down direction and the tether cable will drag heavily over the cab roof and maybe even the hood edge. It is like I may need a nylon block with a groove cut into it to guide the cable across the cab roof while it has minimal load on it, or something of that nature. The roof structure on the M939's are all but strong...... Just the wind blowing across their top can make them oil-can. Ugh...

74M35A2

Well-known member

- 4,142

- 340

- 83

- Location

- Livonia, MI

The boom is done, as pictured. Next step is to remove the bed to set the rear hydro winch in place, cut an access door in the bed floor, and then route the cable up and over the cab. That has not happened yet. I'll have to develop some type of pole for the cable to go up and over the cab.

Csm Davis

Well-known member

- 4,169

- 406

- 83

- Location

- Hattiesburg, Mississippi

What about a roller on the spare tire davit?The boom is done, as pictured. Next step is to remove the bed to set the rear hydro winch in place, cut an access door in the bed floor, and then route the cable up and over the cab. That has not happened yet. I'll have to develop some type of pole for the cable to go up and over the cab.

74M35A2

Well-known member

- 4,142

- 340

- 83

- Location

- Livonia, MI

Yep, something like that. Will probably need to do it right where the vertical post is for support, and may need to be higher to clear the front cab edge. We'll see.

- 2,755

- 2,409

- 113

- Location

- Sunman Indiana

Speaking of "really dangerous ideas"... trying to lift something that requires adding two more 10,000LB capacity tires to what I believe is only a 14,000LB front axle?

Although I'm always up for some destructive testing if someone else is paying the bill!

Sent from my iPhone using Tapatalk

Although I'm always up for some destructive testing if someone else is paying the bill!

Sent from my iPhone using Tapatalk

- 2,913

- 1,609

- 113

- Location

- Czech Republic

It was something I was thinking about also, if I ever come around to do some work my 1973 M51 A3 W/W. My idea was to put two shackles or eyes on the front corners of the dump body, and then either by chains (quicker) or by poles (more stable?) fix to the A-frame. The dump body gives a nice counter weight.

74M35A2

Well-known member

- 4,142

- 340

- 83

- Location

- Livonia, MI

.Speaking of "really dangerous ideas"... trying to lift something that requires adding two more 10,000LB capacity tires to what I believe is only a 14,000LB front axle? Although I'm always up for some destructive testing if someone else is paying the bill!Sent from my iPhone using Tapatalk

Last edited:

- 114,251members

- 167,170threads

- 2,353,452posts

- 6,367online users