Back-in-Black

Well-known member

- 296

- 277

- 63

- Location

- Louisiana

Not disagreeing, just want to know because I hate not knowing exactly what I'm doing with stuff like this.

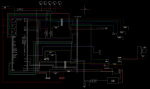

I will want to get with you on governor settings for sure. I haven't actually picked out or ordered an actuator for the throttle but this thing (DGC) will control the actuator to keep RPM as constant as possible using the input from the MPU. Appears to monitor droop, and such and has an option to enable "load control" which I'm guessing will run up the throttle as the current draw (load) increases.

I will want to get with you on governor settings for sure. I haven't actually picked out or ordered an actuator for the throttle but this thing (DGC) will control the actuator to keep RPM as constant as possible using the input from the MPU. Appears to monitor droop, and such and has an option to enable "load control" which I'm guessing will run up the throttle as the current draw (load) increases.