Smallblockfuelie

Member

- 167

- 18

- 18

- Location

- NW Missouri

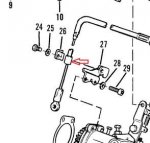

I got up this morning and began going over the MEP-701A I picked up yesterday to determine why the throttle cable didn't work. I quickly found a clamp that is bent or possibly missing a sleeve. The clamp can be tightened some but not enough to tighten against the cable to secure it. The clamp that may be bent is number 26 in this screen shot. The part that makes me consider a missing sleeve is indicated with the red arrow. I'll also try to add a short video after the picture to better show what I am asking about. Thanks.

http://www.youtube.com/watch?v=zK5hpCxv1dw

http://www.youtube.com/watch?v=zK5hpCxv1dw

Last edited: