So, let's start with your first "ASSUMPTION". You are flat out incorrect. 'nuff said on that point. But, ASS-U-ME away if you must

.

This whole discussion is about wear protection. So please, do not insinuate that I am stating anything less than "wear protection is required".

Honda automatics have not used planetary gears since the mid 1960's. 50+ years does not count as a "new" automatic in my book.

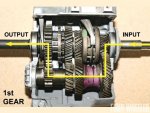

As for gears not being in mesh, let's look at a couple of cutaways.

View attachment 687493View attachment 687492View attachment 687494

Yep, pretty much in mesh all the time.

Regarding Zinc, please provide the reference where the ASTM, the SAE or the API have indicated that low zinc compound formulations are appropriate for all engines. I am not aware of how or why the "American Society for Testing and Materials" would ever specify what is appropriate for an engine. The SAE specifies the viscosity and the API specifies the additive content that must be met in order to be labeled compliant with a particular grade. It is the engine manufacturers which specify what viscosity and grade of oil should be used. If a consumer "chooses" to use an oil that is not certified by the engine manufacturer then they have incurred the wear. High zinc compound oils are readily available and labeled as such. Using a grade of oil not specified by the manufacturer will void your warranty as it is not certified for use in that application. Once again this is a maintenance issue and not a lubricant issue.

I did not say sulfur additives don't work. What I said is that both fluids have to pass the same very strenuous test and do so with a different technology. As for your claim of sulfur additives being best, can you please provide one form of empirical independent testing that proves that statement? Just one will suffice. I have littered my replies with facts to back up my statements and have not once stated opinion in this thread. Would you have the decency to do the same to back up your claims sir? I will take a single certified test result of the four ball wear test wherein gear oil protected better than ATF. Apologies, but without corroborated results you are just providing opinion again.

Porosity - since 90 gear oil has the same viscosity as 40 motor oil, how does that prevent porosity (casting defects) in a case from allowing these fluids to leak out? 80 is close to 30 motor oil which is close to the static viscosity of most ATF. 75W starts out at an equivalent to 10W motor oil.

http://www.afsinc.org/content.cfm?ItemNumber=6933

Regarding pump wear, last I knew when rebuilding engines, power steering pumps, and transmissions all manufacturers recommend checking the oil pump for wear and replacing as appropriate. Oil pumps are wear prone components in all applications. This includes vane pumps as well as gear displacement pumps. Can you please show us where the Chrysler service or repair manuals state that the oil pump in their transmissions does not need to be checked for wear because their design is just that much more special than anyone else's?

The choice of the "correct" style of pump to use has a lot of factors associated with it.

http://www.designworldonline.com/the-right-pump-for-the-job/#_

One last point. You keep insinuating that I have no experience in the "industry" as you call it, and continue to deign my credentials without knowing one thing about me. If you read through this thread, I have never once called into question anything about you personally. I have only refuted the opinions you have provided with fact based on my years of experience not only in the repair industry but also as an engineer. Please stick to facts and do not resort to personal attacks. I enjoy the debate and hope you do as well, but stick to the facts man and back up your claims.