peakbagger

Well-known member

- 732

- 350

- 63

- Location

- northern nh

My SEE has had a persistent hydraulic leak out around one of the boom cylinders since I got it. It has always worked but has been a housekeeping issue as it leaks 365 days a year even when sitting all winter. Lately I have been doing some "hardcore" digging in the local rocky soil and noticed its leaking more when I am using it. I had bought seal kits from Foxkits.com several years ago in anticipation of needing to do a rebuild.

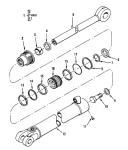

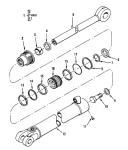

I did the tear down yesterday and while replacing the various seals, in general they looked real good, I was expecting far worse. When I got the internal lip seal #6 on the drawing, the lip definitely is pointing out towards the rod end. The lips larger diameter is facing right on the parts sketch below. This really does not make sense to me. as the return pressure on the cylinder is on the left. In theory the pressure int he cylinder would push on the lip and push it outwards making the seal against the rod yet this cylinder on the See has it facing the other direction and it looks like its never been touched.

The question is does anyone know which was the lip seal should be facing?. My guess is someone long ago put the seal in facing the wrong direction and since the SEE has minimal hours and worked despite the leak, that the military just didnt mess with it.

I really do not want to re-assemble and have to take apart again.

I did the tear down yesterday and while replacing the various seals, in general they looked real good, I was expecting far worse. When I got the internal lip seal #6 on the drawing, the lip definitely is pointing out towards the rod end. The lips larger diameter is facing right on the parts sketch below. This really does not make sense to me. as the return pressure on the cylinder is on the left. In theory the pressure int he cylinder would push on the lip and push it outwards making the seal against the rod yet this cylinder on the See has it facing the other direction and it looks like its never been touched.

The question is does anyone know which was the lip seal should be facing?. My guess is someone long ago put the seal in facing the wrong direction and since the SEE has minimal hours and worked despite the leak, that the military just didnt mess with it.

I really do not want to re-assemble and have to take apart again.