- 481

- 248

- 43

- Location

- Qualicum Beach BC

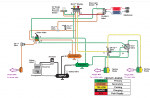

This is a repository for the information I'll be uploading on splitting the single circuit brakes and modifying the air system.

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

There are one way checks at the inlets of the primary and secondary tanks. The symbols with the arrows. I'd like to see the diagrams of the what and why in your US regs.The check valves need to be installed in front of the air tanks. Just think of a stream of water. No water can be allowed to come back up-stream. Of course that is USA regulations. I don't know about Canadian laws.

You know what is so frustrating ? I had those manuals for YEARS and never used them . The moment I tossed them away I needed them ! This has happened to me several times now. It's gotten to the point that I'm afraid to throw away anything anymore. In fact I have these old 1955 Cadillac and Pontiac bellhousings and extension housings for the HydraMatic laying around, getting in the way but I'm afraid as soon as I throw them into the scrap bin someone will ask if I have them ! If I leave them outside they will get rust on the machine surfaces and be useless. So they just take up shop space.Story of my life too. I tossed so many things in the move last year. It'll be the better part of this year till i can start reorganizing after construction is completed. Then I'll know all the things that slipped through my fingers.

Thanks for looking though

We get it, advertisements are annoying!

Sure, ad-blocking software does a great job at blocking ads, but it also blocks useful features of our website like our supporting vendors. Their ads help keep Steel Soldiers going. Please consider disabling your ad blockers for the site. Thanks!