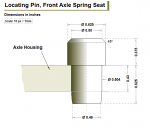

Locating pin for front axle spring seat.

Since this isn't a part you would find in the manuals I made a quick drawing, for anyone to see the dimensions of that locating pin. (below...)

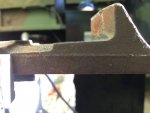

If I had this issue (Valence's) I would look for a new replacement pin, or simply make one, out of a short 5/8" bolt (grade 5). Then either pull- or push-out- the remaining piece.

There are two ways: the "correct" - and much more labor-intensive way which would be pulling that side axle shaft, then get a punch and knock the broken end all the way down into the housing. Then get it out with a telescoping magnet or similar.

(I would only go this route if it was time already to service the inner oil seal, or the knuckle boot or kingpins...)

Or... much faster - if it worked: drill & tap the remaining piece to create a 3/8"-16 threaded hole, about 1/2" deep. Then look for some kind of a 3/4"-long bushing (or a 3/4" hex nut; any 3/4"-thick spacer; etc..), with a 5/8" I.D. and use a section of 3/8"-16 threaded rod plus nut and flat washers, to make it work as a puller tool.

Better don't drill all the way through if you want to avoid shavings inside the axle housing!

After screwed in place (puller nut on, but still loose) get a hammer and give that rod some good wacks from the top, to help breaking loose the offending part. Use lots of PB-blaster or equivalent!

Alternative, if you had a nice oxy-acethlene torch: with rod inserted, quickly heat up that part and let cool. It will shrink and may come out with almost no effort.

G.