shenkmen

Active member

- 1,107

- 12

- 38

- Location

- Lancaster, PA

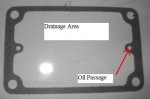

Hi there, my compressor gasket was leaking so I decided it was time for replacement. It's now leaking worse. No sealant was used. The work was done in a heated garage. Drove it twice an re-torqued it twice. All work was done by an ex deuce mechanic.

Our guess is the bottom of the compressor is warped.

Possible solutions...

Cheers.

Our guess is the bottom of the compressor is warped.

Possible solutions...

- New compressor - ouch $$.

- Double gasket.

- A home made gasket made from thicker material.

- Mill the base of the compressor.

- What are your thoughts and/or experiences on this?

- If we go the home made gasket route what type of material would you recommend?

- Can we assume the compressor is getting enough oil at this point? The oil isn't pouring out but it is leaking nicely.

Cheers.

Last edited: