dmetalmiki

Well-known member

- 5,523

- 2,036

- 113

- Location

- London England

I have spent hours with the .M.s which are simply vague in the extreme just pictures and hints absalutely no instructions.

I find the same in help forums.

How to turn DOWN the fuel on the 5 ton LDS 465 engine.

A big headache later and all and every answer is for turn up the fuel, On a deuce!.

Many answers (NOT one I would ever give!) are somehat like this.

a)"the adjustment is on the pump (yes!)

b)Undo the first nut DO NOT TURN THE SCREW or the ? will snap) (err ok!)

c)Undo the second nut and TURN??? the SCEW? one or two flats!!??? (Thought you said DO NOT TURN THE SCREW!)

And...WHICH WAY???? in out up down..this type of advice drives me nuts and just gives me a headache.

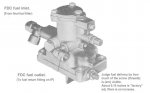

d)Then there is the picture of 'how to' Hmm, OK..JUST a picture nothing else! Great!

I will, or someone with understandable concise grammar will, (hopefully) step in and answer these questions without innuendo or 'guesswork'. or pictures with NO information on.

How to adjust the injection pump fuel down OR up. On the code 'B' (C,D,E,)and 'F'? fuel pumps. on the L.D.S series engines.

(yes the deuces may be the same procedure.)

A) Free the first lock nut?

B) DO NOT allow the screw to turn?. So, HOW do you PREVENT it from turning?

C) Turn the Inner nut (Which way to lean = less smoke. or which way to richen the mixture? = more smoke.

I am Guessing the second nut (NOT the screw?) moves in or out to change the rate. NOT the mixture as that screw contacts the levers linked to the governor mechanism? But, Then what is securing the SCREW or enabling it to 'Move in or Out?. I am guessing again that the Governor mechanism is pushing? that screw out, OR, or pulling that screw in?..and the NUT lets it 'Go In' when Undone or or Pulls it out when tightened.

Logic tells me that the inner Nut could be 'Affixed' to that screw which when turned creates the 'adjustment, in Weak = no smoke or out rich = smoke. And the first nut is a lock nut only.?

Obviously the first nut can't be affixed to the screw as it would not allow adjustment.

BUT, By way of 'common sense' (and looking at the schematic) both nuts can be undone, and the adjustment is by way of that SCREW being turned in or out to create adjustment by way of the 'movable plate' inside. As advised NOT to do! and thus NOT allowing the SCREW to turn and break or loose the 'linkage' going to the servo piston.

Interpretation, factual concise instruction, and or advices and corrections where necessary greatly appreciated.

And I am sorry for "Imposing" headaches! on anyone ploughing through all this to apply the 'fix'. But at least it will make perfectly clear how to carry out the adjustment, with the correct do's and dont's to ALL UN-sundry, old, young, experienced, inexperienced, or, just plain curious!.

Ref. TM-2910-226-34. Page Para. 1-30. Fig. 10-28 and 1-29.

I find the same in help forums.

How to turn DOWN the fuel on the 5 ton LDS 465 engine.

A big headache later and all and every answer is for turn up the fuel, On a deuce!.

Many answers (NOT one I would ever give!) are somehat like this.

a)"the adjustment is on the pump (yes!)

b)Undo the first nut DO NOT TURN THE SCREW or the ? will snap) (err ok!)

c)Undo the second nut and TURN??? the SCEW? one or two flats!!??? (Thought you said DO NOT TURN THE SCREW!)

And...WHICH WAY???? in out up down..this type of advice drives me nuts and just gives me a headache.

d)Then there is the picture of 'how to' Hmm, OK..JUST a picture nothing else! Great!

I will, or someone with understandable concise grammar will, (hopefully) step in and answer these questions without innuendo or 'guesswork'. or pictures with NO information on.

How to adjust the injection pump fuel down OR up. On the code 'B' (C,D,E,)and 'F'? fuel pumps. on the L.D.S series engines.

(yes the deuces may be the same procedure.)

A) Free the first lock nut?

B) DO NOT allow the screw to turn?. So, HOW do you PREVENT it from turning?

C) Turn the Inner nut (Which way to lean = less smoke. or which way to richen the mixture? = more smoke.

I am Guessing the second nut (NOT the screw?) moves in or out to change the rate. NOT the mixture as that screw contacts the levers linked to the governor mechanism? But, Then what is securing the SCREW or enabling it to 'Move in or Out?. I am guessing again that the Governor mechanism is pushing? that screw out, OR, or pulling that screw in?..and the NUT lets it 'Go In' when Undone or or Pulls it out when tightened.

Logic tells me that the inner Nut could be 'Affixed' to that screw which when turned creates the 'adjustment, in Weak = no smoke or out rich = smoke. And the first nut is a lock nut only.?

Obviously the first nut can't be affixed to the screw as it would not allow adjustment.

BUT, By way of 'common sense' (and looking at the schematic) both nuts can be undone, and the adjustment is by way of that SCREW being turned in or out to create adjustment by way of the 'movable plate' inside. As advised NOT to do! and thus NOT allowing the SCREW to turn and break or loose the 'linkage' going to the servo piston.

Interpretation, factual concise instruction, and or advices and corrections where necessary greatly appreciated.

And I am sorry for "Imposing" headaches! on anyone ploughing through all this to apply the 'fix'. But at least it will make perfectly clear how to carry out the adjustment, with the correct do's and dont's to ALL UN-sundry, old, young, experienced, inexperienced, or, just plain curious!.

Ref. TM-2910-226-34. Page Para. 1-30. Fig. 10-28 and 1-29.

Last edited: