If you do a "google scholar" search, you can limit results to journal publications. A search for "continental aviation variable compression ratio" yields two interesting papers:

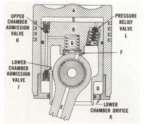

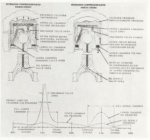

"A variable compression ratio engine development" by W. A. Wallace of Continental and F. B. Lux of the Army Tank Automotive Center; published in 1963 at the National Powerplant and Transportation Meeting. I can view but can't download the paper. However, I was able to attach two cutaway views of the piston.

"Recent Developments in Variable Compression Ratio Engines"; 660344

In an effort to produce military tank engines with more power per cubic foot of bulk and more power per pound of weight, Continental Aviation and Engineering Corp. has applied the Variable Compression Ratio (VCR) piston to an already developed, aircooled diesel engine. In this engine design, compression ratio is automatically varied within the piston by the use of hydraulic circuitry employing a control valve operating in response to changes in peak combustion pressure. To accomplish the dual objectives of smaller volume and lighter weight, Continental is developing, under U.S. Army sponsorship, an engine that is currently capable of producing 1.3 gross horsepower per cubic inch of piston displacement. Weight, including all engine and transmission cooling equipment, is 2.3 lb/gross horsepower. This paper presents the developmental background and some interesting technical details of this project.