rustystud

Well-known member

- 9,402

- 3,392

- 113

- Location

- Woodinville, Washington

One of the advantages of being a "crusty old mechanic" is all the knowledge floating around your noggin. One of the "disadvantages" is all that knowledge floating around your now OLD noggin ! Things get lost up there !

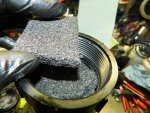

Case in point. I'm building up a supply of spare parts for the deuce for the "Great Alaskan Adventure" . Also just to have around here just in case. I've been taking parts off my older M35 trucks and cleaning them up and repairing them and then storing them away. So here I am cleaning up all the rust and old grease from a couple of drag-links and putting them back together and storing them in ABS tubes. Now I have rebuilt this style of drag-link for years, ever since I was an apprentice at IHC in Tukwilla, WA. IHC loved this style of drag-link and so do I ! It is the only one that will last a lifetime if taken care of. They must be cleaned of road grime and old grease and rust every few years to keep them operating smoothly and safely.

So here I am reassembling them and putting them away in storage. Latter that evening I started thinking about how I assembled them. There is a specific way they must go together or you risk injury from an accident ! I have seen this happen in my first year as an apprentice. An older journeyman put one together next to my stall ( I watched him do it) and when the truck went out the driver lost control and hit the bridge supports to I-5 !

So I'm trying to remember how I put them together and I cannot. So the next day I take them apart and the first one is correct, but the second one is not.

I didn't look at the manual (a mistake older mechanics do all the time) as like I said earlier I have done this job many, many times before. What I did was install the "safety plug" shaft-end into the drag-link instead of into the spring. What this will cause is the spring will not be fully compressed and will allow the steering to shake violently.

Picture two shows the correct orientation of spring and ball seat and safety plug.

The two shaft ends must go into the spring where they will be compressed together. The problem arises due to the fact that the drag-link has a socket on both ends (pictures 6 and 8 ) and one will assume that the shaft ends fit into them, which it does on the "Pitman" arm side.

Picture one shows the correct way to install safety plug, spring and ball seat for the "steering arm" side. Picture 9 shows the correct way to install the parts for the "pitman arm" side.

I hope this little thread helps anyone who is going to be cleaning their drag-link ends.