JTRUCKJMC

New member

- 17

- 3

- 3

- Location

- W.P.B., FL

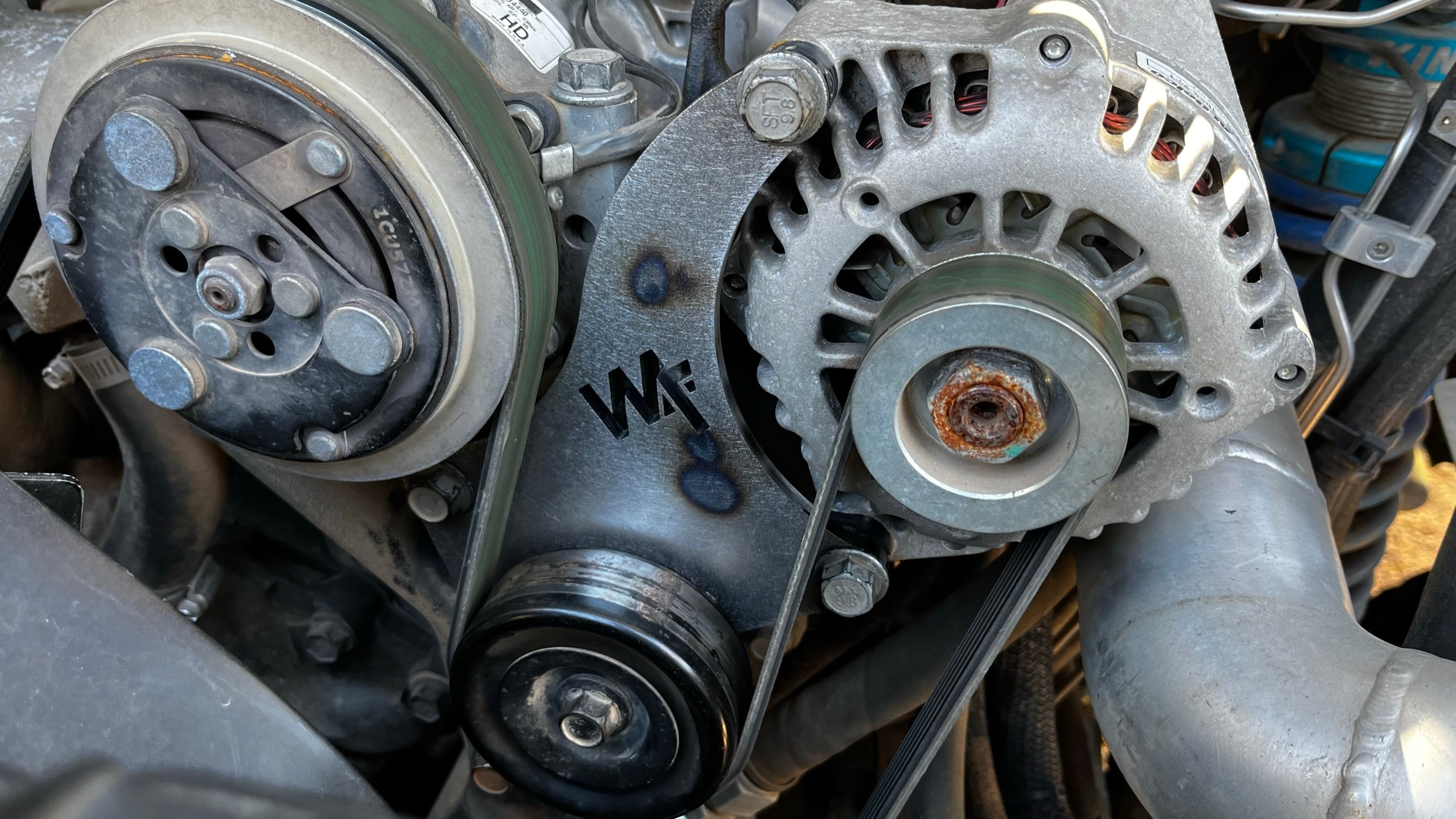

Does any one know the Type (CS130?) and p/n's of the alternators on a 6.5 Diesel CUCV

II. Are they isolated ground. Updating a 6.2 with serp set up with 24/12 volt system. THX

II. Are they isolated ground. Updating a 6.2 with serp set up with 24/12 volt system. THX