- 34,010

- 1,827

- 113

- Location

- GA Mountains

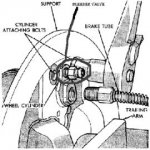

Gang, here are 2 pics of my bleeder. You can see that the tank line has a ball valve and a quick coupler from an air line. It then connects to a second hose that has a tee and a 6" nipple that screws into the MC cap. There's a plug in the top of the tee but eventually it will have a pressure gauge. You can't install the cap as it's pictured. You have to put the cap on then screw the nipple in. I have a second hose not pictured just for filling the MC. It works flawlesssly and you can just keep the BFS right in the bleeder. That MC cap is also an extra but you could easily use your own cap by just removing the vent line fixture. When shopping for a sprayer, find one with a pressure release valve,

Attachments

-

217.6 KB Views: 4,501

-

158.5 KB Views: 4,526