I'll try to answer the three main questions here:

It looks to me like there will still be moisture that can enter the M/C with DOT5 in it (just like it can with a M/C filled with DOT3). Just because water won't mix with DOT5 doesn't mean water can't get into the system. To me, it stands to reason that if moisture gets into a DOT5 system that it will settle in the low points of the system. I could be wrong but I've heard this argument before and it seems reasonable.

Yes, water will drop to a low point in a DOT5 system. But that point is generally in the sump of the M/C. Any water that got past the sump, would probably never leave the master cylinder... but assume that it did, and made its way to the wheel cylinders while the system was being bled, it would potentially cause rusting. Typically, it doesn't because there is little or no oxygen in the trapped water, and the cylinder walls of the cast iron wheel cylinders will have soaked up a protective coating of silicone quite thoroughly.

One has to think about how the water would get into the system in the first place...DOT3 is so hygroscopic that it will draw moisture out of the air, and contaminate the fluid in the M/C sump. DOT5 cannot do this.

I've seen rust (and lots of it) in trucks from GL. One would assume that all the trucks comming from GL right now were running DOT5 ( I think the trucks that had rust issues had "use DOT5" written on the dash). Now I will admit that there's no telling what was actually put into the M/C of a GL truck so that could have been the problem but I have seen rust in a supposedly DOT5 system.

The switch over from DOT3 to DOT5 came in phases. First, the supply depots were sent DOT5, and ordered to return all of the DOT3 in their possession. And then the PMCS details were ordered to flush and replace the DOT3 as time became available, or when the trucks came in for brake service. The order said to use DOT5 to top off any system regardless of whether it contained DOT3, or DOT5. The powers that be felt that doing a power flush with DOT5 would do an adequate job of clearing a system of its old DOT3 fluids.

I have personally tried this, and I can tell you that it doesn't do a thing to the fluid in the wheel cylinders. I have taken apart wheel cylinders where I tried to power flush the DOT3 out with DOT5, and have found them to still be 2/3 full of DOT3!

People that ford a lot, and let the water submerge the brake drums completely will see failures even with DOT5. This is because water, and mud, always leaks past the wheel cylinder's boots, and gets into the space between the aluminum piston, and the cylinder walls... a space that is supposed to only contain air.

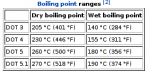

I guess its just an extra precaution. Dot 5 will NOT attract moisture like 3&4 will so when temp cycles cause the cast iron peices of the sytem to sweat it SHOULDNT draw it in. Who knows what gets put into the system before we get em. Could it be the boil temp is higher with dot 5 so they thought it was a better move?

The reason behind the switch was most certainly due to rampant brake failures when trucks with DOT3 fluid were left to sit for months at a time without going anywhere. Vehicles that sit unused for long periods are the only vehicles I have ever had a failure with DOT3.

I have had two sorts of failures with DOT5: One is due to leakage at fittings. DOT5 will creep through poorly done fittings that would have easily held DOT3. The other was due to leaking around a piston cup on a cylinder that had the wrong type of expansion spring.

-Chuck