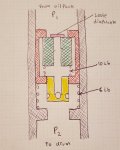

Ok, here is another concept for a valve that you could just put on each leg of you brake lines to shut one down in case of a failure, and keep the other functional.

The drawing is by hand, so not to dimension or anything, but the concept should be clear. This is to shut off fluid flow in the event the pressure on the other side of the valve drops below 10psi during braking.

P2, should be whatever pressure the drum return springs provide. Def more than 10 lbs. The line will be hydrolocked and stay at that pressure untill the pads make contact. The RPV (the red body) will not move in that state.

If all is good, the 10psi valve (green body) will open and brake fluid will flow. P1 = p2 from this point on, and the red body will stay put, especially with the spring behind it. That part is also possibly dependant on the green surface area being larger that the red. The drawing is not representative of that.

If the line return pressure from the drums is less than 10lb, the brass end that is screwed into the RPV will bottom out and shut off flow. Again, this is only while the pedal is pressed.

When not in use, the valve will reassume its resting position and let fluid flow freely back upstream. Your stock master cylinder already has a 10psi RPV in it, so you dont lose that nicetie.

I've designed a simpler version, but this one is based on an off the shelf valve you can get all day for 10 bucks. (Residual pressure valve) theyre everywhere.

Whooo!

Let me know what you think.