I had actually thought about this several years ago and worked up some numbers way back when. The numbers looked acceptable back then but I didn’t have any time to pursue it and shelved it for later. I am glad someone else is exploring the possibilities.

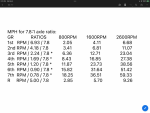

Here are the numbers I came up with for 395/85R20 tires(~146.6” circumference).

MPH for 7.8:1 axle ratio:

View attachment 892322

*= lockup. The TCU initiates lockup somewhere in 3rd gear, which is probably why the 2-3 shift feels a little harsher than the rest(Its also a bigger % jump). if accelerating, the TCU maintains lockup continuously 3rd thru 7th both up and downshifting. Before lockup the Torque converter gives you an infinite slip until you reach TC stall(1400-1600RPM) at that point you have an added 2+:1 torque multiplication. As the turbine unstalls/starts to accelerate(truck moving) The torque multiplication decreases from ~2:1 back towards 1:1. This added variable torque multiplication is the true magic of the Allison automatic config.

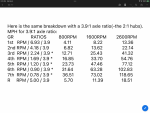

Here is the same breakdown with a 3.9:1 axle ratio(minus the 2:1 hubs).

MPH for 3.9:1 axle ratio:

View attachment 892321

Driveshaft RPM @ ~60MPH cruise in 6th gear with the 3.9, will be ~1685RPM down from ~3333RPM@60MPH with the 7.8 final ratio. That is significant!

7th gear will probably no longer be used automatically(i think cruise speeds in excess of 65 or so are not wise), but it is still there, and under certain conditions you may be able to use it, although the shift point criteria may need to be changed to get it to stay there. With a 3.9 final, ~60 MPH in 7th would be 1314 engine RPM. Wether that produces enough torque to be sustainable would need to be tested. I have seen different numbers between mid 1450-1550 RPM for peak torque point so…

Not using 7th is insignificant IMO as Allison programs 6th gear(our 7th) out of many applications using the 3060 transmission(the core of our 3070). I occasionally drive one(old FL-50 ambulance with 5 speeds and a cummins engine

) “How can I get 6th gear back” is a popular topic on the “Skoolie” forums as many school busses were programmed for only 5 of the 6 available speeds from the 3060. The transmission simply doesn’t care…

As mentioned the axles are gross milspec overkill even for one of our trucks grossly overloaded. Because of the weights we typically do run, I do not think loosing the 2:1 hub final will significantly effect their operation.

I think the benefits of dropping the engine RPM closer to engine peak torque at highway speed(60MPH with 3.9 in 6th gear will yield 1517 engine RPM) and cutting the driveshaft RPM IN HALF on these very steep driveshafts far outweigh any possible downsides that I can see… Thats why I was attracted to the concept way back when…

The only place I would be curious to see final performance is in slow speed wheeling. The low speed torque manipulations provided by the torque converter in the Allison are where this combination really shines though. I am sure it will be different, but I do not think that difference will be significantly different/unusable at slow speed Because we have that added 6.93:1 first gear.

Would love to come wheel your truck, but don’t think I am getting to Indiana anytime soon…

You can put me down for a set though

edit: Easier to read the tables as screenshots. Forgot how difficult it was to do columns in HTML