I worked up this information for a FB discussion and thought I would share it here:

Several have reported pulling hills at highway speed better with the new hubs. This actually falls in line with published information. You start running the RPM past peak torque, the available torque falls off drastically. At 2600 RPM it is closing in on half what it is at peak torque…

With RPM increase beyond pk, You have more torque pulses, which is why HP increases(to a point), but they are becoming shorter and shorter. At some point, especially in a longer stroke, the pumping losses overcome the ability to generate torque, basically the engine is tripping over/braking itself. This is a horribly inefficient way to operate.

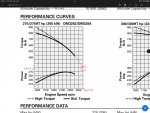

This 3126 power curve illustrates this very well. If you are rolling down the highway at peak torque, and run up onto a hill, as long as the torque requirements are lower than the torque available at that RPM, you will just drive over it.

If you are rolling along at 2600RPM/~half peak torque, it is far more likely you will have to drop gears(and speed) to lower the engine toward peak torque to pull up the hill…

Some calculated highway numbers that support the same or better highway performance people are noting:

Air resistance notwithstanding…

My 3116 truck stock with 2:1 hubs @2600 RPM makes maybe 350ft/lb of torque? X.78(7th) and 7.8 axle - losses, can generate ~755# of thrust@ 59MPH

That is enough to pull 20K up a 2.16deg/3.77% slope.

To get back to peak torque and 1337# of thrust(3.8deg/6.64% grade) I have to drop to 35MPH…

Minus the hubs @1550 RPM(620ft/lb PK Torque), X .9(6th) and 3.9 axle - losses, can generate ~857# of thrust@ 61MPH.

That is enough thrust to pull 20K up a 2.45 deg/4.28% grade…

If I drop back to 5th @ peak torque, that will give me 1210# of thrust @~45MPH, enough to climb 3.6deg/6.12% slope

If I drop to 4th at peak torque thats still ~30MPH, but a 40% increase in thrust @1694# or 4.86/8.5%@ 620ft/lb sustained rear ds torque. I think there will be a point in 4th between peak torque and peak HP where I will still beat my 2:1 hub truck output(1337#) at a speed greater than 35MPH…

Minus the 2:1 hubs, at pk torque and 61MPH, in 6th, with the 70/30 torque split from the transfer case, that is ~332ft/lb continuous torque into the rear driveshaft and ~142ft/lb into the front. If I recall the specs for the type 16 driveshaft, they are rated for ~2500 or 2700ft/lb continuous torque. (Cant find that spec right now

)…

View attachment 898953