army70deuce

Member

- 106

- 3

- 18

- Location

- Anderson, SC

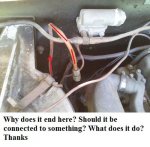

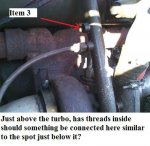

Just got my Deuce the other day and it runs pretty well while driving, unfortunately it idles at around 400rpm according to the tac (and doesn't like it) vs the 650-800rpm that is specified in the manual so I'm trying to track down the issue, being a guy familiar with carbs my mind races to air leaks. I'm attaching some pictures with big arrows to point to my questions because I have found a few places where there are holes that I would think should be connected to something and lines that are not connected, and no they don't match up with each other that would be too easy. Also I have a question on what some things are, please be patient with me, I'm not familiar with multifuels...yet.

All comment and suggestions are welcome, Thank you for your help with this.

All comment and suggestions are welcome, Thank you for your help with this.

Attachments

-

41.4 KB Views: 138

-

40.7 KB Views: 140

-

20.5 KB Views: 138

-

21.5 KB Views: 132

-

41.5 KB Views: 135

-

40.8 KB Views: 139

-

39.8 KB Views: 139

-

57.9 KB Views: 136