So are you going to run these on the rear with the hubs flipped? If so, I'd imagine they'd be close to flush with the bed sides as the Canadian wheels are basically flat-faced and still seem to look like they are in under the bed sides a few inches. If you are running with hubs flipped, are you concerned about accelerated bearing wear?

I think the truck would look good with the stock wheels on the front and these on the back. If you are going to run the 11.00's I don't see the need to widen the front wheels out to a wider track width just to have all 6 wheels look the same. I know it's your truck, I'm just thinking out loud more than anything.

........

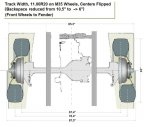

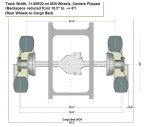

Yeah, I've flipped the hubs. I would really like to run Canadian beadlocked wheels, but they're esspensive and I don't like how far inboard they are under the truck. If I didn't care about keeping the front/rear track-width the same, I would just have left the back hubs set up for duals and only run the outer wheel/tire. I'm not concerned about wheel bearing wear. I'm a little bit concerned about kingpin bushing wear though. The scrub radius isn't going to be great, but after weighing all my options, I think this is the best compromise for me right now.

I think it will bring the tires close to even with the edge of the front fenders. Prolly add a little sability to the 109 and look pretty good. I doubt there will be any MORE bearing wear than normal. Overall a good mod.

I think the front tires might actually peek out from under the front fenders just a bit. Like I said, might end up a little wider than I want to be, but there's no middle-ground here. It's one or the other.

Nice job so far. i would probably use the trailer as a trueing jig .You can spin the the wheels easier without turning the axles and spider gears.Also you will only have to jack up one tire that way.

Are the riveted wheels the same diameter all the way from bead to bead ?would it be possible to put the center wherever you wanted?An air chisel with a sharp bit makes quick work of rivet heads and then a punch bit on the air chisel is great for knocking the rest out of the hole.Plus it's cheaper than a torch

That's a good idea about the using the trailer, but I don't have a 220V outlet over where my trailer is parked. It'll just be easier to jack-up one axle than to shuffle all the trucks and trailers around my yard.

Unfortunately, the rivet wheels are not the same ID from bead-to-bead. I was hoping that might be the case, but the part of the rim shell that the center-section is riveted to is raised slightly, so you can't really put the center-section anywhere else. It's either in or out (stock or flipped). But I was looking at it today, and I think I might be able to cut off part of the lip on the center-section (where the rivet-heads were) and then weld it on the very outside of that ridge on the shell. I think that might keep the wheels tucked in about 1-1.5" more per side. Going to have to play around with it to see what's going to work.

Thanks for the tip about the air chisel. I don't have one, but have been meaning to buy one for a while. Maybe this would be a good excuse. I've got enough wheels to do that I could try a few different techniques.

You're probably doing a great job with the oxy torch, but I wanted to lend my opinion that one place a plasma cutter shines is cutting out rivets.

I know, not everyone has access to a plasma, but if you can lay your hands on one, it will allow you to make really nice clean and quick swipes of rivet heads.

I hear yah, just don't have access to a plasma right now. Would be nice...