- 4,437

- 3,743

- 113

- Location

- Fort Worth, Texas

The 1078 I recently acquired runs but wont go into gear. The PBC (push button controller - Wtec3) is giving me an active code for 46 27 - Overcurrent, A-High Solenoid Circuit. Clearing the code does not work, the condition is active and preventing engagement. The relays in the PDP click when pushing D-N-R but no change in gear is being displayed on the PBC, it's always in neutral. Mode does light up but no engagement. If the truck is off then turned on and quickly put into D or R it will display for a second before reverting to Neutral when the code is active. No engagement. The code is always active.

A quick google shows it's either a short to ground or solenoid issue for this code. Now to the TM..

The front table list on TM 9-2320-365-20-2 shows the following:

-----------------------------

WTEC III Transmission Pushbutton Shift Selector (TPSS) DisplaysMain Code 42, 44, 45, 46, and/or 69 and Any Sub Code

-----------------------------

However when on that troublshooting guide the title EXCLUDES Main Code 46. (Titles copied from the .pdf TM file.)

-----------------------------

WTEC III TRANSMISSION PUSHBUTTON SHIFT SELECTOR (TPSS) DISPLAYS MAIN CODE42, 44, 45, AND/OR 69 AND ANY SUB CODE

-----------------------------

I want to point this out as either it's a type-o or undocumented. I'm leaning toward typo as you will see shortly..

I've been following the TM and hunting for the common problems but no luck. Suprman has been giving me pointers but this one is going beyond end of the TM. The transmission body harness was in shambles due to age and would require replacement anyway. I ohm'd the harness following the chart on page 2-1525 Table 2-34 & 2-35 and here's the results.

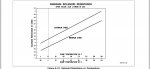

I've got a clear ohm drop on circuit P119M to P119B. Note that all other ohms are very close to each other (if not the same due to my hand) but all are off the chart on 2-35. According to this resistance it should be 122F to 140F inside the transmission but it was a nice 78F outside and the truck was cold. I went to my parts donor M1078 and performed the same test to verify finding and all came back at 4.0-4.1 ohms. The resistance is consistent between both truck harnessess but not right for the temp for some reason. Thoughts?

Knowing I've got a bad harness on the "new-to-me" truck by looking at it I removed it. I then swapped over the harness from my donor (which looked way better). I plugged it in and still actively coded 46 27 - Overcurrent, A-High Solenoid Circuit. I performed the ohm test again and it ohm'd exactly the same with the 1.2 ohm on the same circuit. I decided to replace the PBC/Push button controller just to be sure it wasn't something stupid and I temporarily installed a known good TCM under the PDP. Code still active.

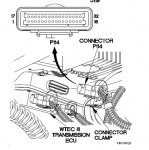

The TM asked me to conduct a continuity test from the J119 connector on the cab to the P114 connector on the ECM but I skipped that. The short adapter harness with the blue plug (Connector P114) looked to be very recently replaced. I physically checked it and no cuts or damage to the outer casing. The pins on the connector looked good.

Reference:

(ss keep rotating my pictures..idk why)

(ss keep rotating my pictures..idk why)

At this point the TM says either replace the harness OR replace the transmission ECU. It's a 2 step process. End of diagnostics. I wasn't satisfied with this and the issue still persists. The transmission body harness was replaced with no change and the transmission ECM didn't make a difference either. This leads me back to the suspiciously bad 1.2 ohm'd circuit P119M to P119B.

Reference:

I removed the main transmission harness off the transmission pigtail connector that is located on the passenger rear side of the transmission. I tried to ohm the transmission directly using the J119 plug diagram but it doesn't match up to the unmarked pins on the pigtail. Going in blind I made loose note of any suspiciously low ohm'd connections and used the mating J119 letter diagram to keep reference. The transmission body harness does not start and end on the same letter (i.e. B to B on each end) as some pins are absent on the transmission pigtail or the harness connector doesn't have female receptors in those slots. So in this case pins P119M to P119B do not lead to pins P and B on the transmission pig tail.

I found connection A to G was reading 1.0 ohm which was very close to the 1.2 ohm reading on P119M to P119B on the main harness. I found most pins either had no continuity or a steady 4.0 ohms like the harness showed. I found a secondary circuit A to V (i think) that also reported 1.0 ohm that may share the same solenoid, but also another one that reported a .7 ohm. At this point I stopped as it was blind guessing without any guide from Allison.

So recap at this point. PBC is good. Transmission ECM is good. P114 harness in the dash looks new. Transmission body harness was replaced and ohm'd the same as the "bad" one with one circuit reading 1.2 ohms. Last thing is an actual bad solenoid inside the transmission causing this. Low resistance = high voltage = code 4627 Overcurrent, A-High Solenoid Circuit...or so is my thinking. If some people would be kind enough to do the solenoid ohm test and report their findings I'm sure that would help me and future people with this issue.

A quick google shows it's either a short to ground or solenoid issue for this code. Now to the TM..

The front table list on TM 9-2320-365-20-2 shows the following:

-----------------------------

WTEC III Transmission Pushbutton Shift Selector (TPSS) DisplaysMain Code 42, 44, 45, 46, and/or 69 and Any Sub Code

-----------------------------

However when on that troublshooting guide the title EXCLUDES Main Code 46. (Titles copied from the .pdf TM file.)

-----------------------------

WTEC III TRANSMISSION PUSHBUTTON SHIFT SELECTOR (TPSS) DISPLAYS MAIN CODE42, 44, 45, AND/OR 69 AND ANY SUB CODE

-----------------------------

I want to point this out as either it's a type-o or undocumented. I'm leaning toward typo as you will see shortly..

I've been following the TM and hunting for the common problems but no luck. Suprman has been giving me pointers but this one is going beyond end of the TM. The transmission body harness was in shambles due to age and would require replacement anyway. I ohm'd the harness following the chart on page 2-1525 Table 2-34 & 2-35 and here's the results.

I've got a clear ohm drop on circuit P119M to P119B. Note that all other ohms are very close to each other (if not the same due to my hand) but all are off the chart on 2-35. According to this resistance it should be 122F to 140F inside the transmission but it was a nice 78F outside and the truck was cold. I went to my parts donor M1078 and performed the same test to verify finding and all came back at 4.0-4.1 ohms. The resistance is consistent between both truck harnessess but not right for the temp for some reason. Thoughts?

Knowing I've got a bad harness on the "new-to-me" truck by looking at it I removed it. I then swapped over the harness from my donor (which looked way better). I plugged it in and still actively coded 46 27 - Overcurrent, A-High Solenoid Circuit. I performed the ohm test again and it ohm'd exactly the same with the 1.2 ohm on the same circuit. I decided to replace the PBC/Push button controller just to be sure it wasn't something stupid and I temporarily installed a known good TCM under the PDP. Code still active.

The TM asked me to conduct a continuity test from the J119 connector on the cab to the P114 connector on the ECM but I skipped that. The short adapter harness with the blue plug (Connector P114) looked to be very recently replaced. I physically checked it and no cuts or damage to the outer casing. The pins on the connector looked good.

Reference:

(ss keep rotating my pictures..idk why)

(ss keep rotating my pictures..idk why)At this point the TM says either replace the harness OR replace the transmission ECU. It's a 2 step process. End of diagnostics. I wasn't satisfied with this and the issue still persists. The transmission body harness was replaced with no change and the transmission ECM didn't make a difference either. This leads me back to the suspiciously bad 1.2 ohm'd circuit P119M to P119B.

Reference:

I removed the main transmission harness off the transmission pigtail connector that is located on the passenger rear side of the transmission. I tried to ohm the transmission directly using the J119 plug diagram but it doesn't match up to the unmarked pins on the pigtail. Going in blind I made loose note of any suspiciously low ohm'd connections and used the mating J119 letter diagram to keep reference. The transmission body harness does not start and end on the same letter (i.e. B to B on each end) as some pins are absent on the transmission pigtail or the harness connector doesn't have female receptors in those slots. So in this case pins P119M to P119B do not lead to pins P and B on the transmission pig tail.

I found connection A to G was reading 1.0 ohm which was very close to the 1.2 ohm reading on P119M to P119B on the main harness. I found most pins either had no continuity or a steady 4.0 ohms like the harness showed. I found a secondary circuit A to V (i think) that also reported 1.0 ohm that may share the same solenoid, but also another one that reported a .7 ohm. At this point I stopped as it was blind guessing without any guide from Allison.

So recap at this point. PBC is good. Transmission ECM is good. P114 harness in the dash looks new. Transmission body harness was replaced and ohm'd the same as the "bad" one with one circuit reading 1.2 ohms. Last thing is an actual bad solenoid inside the transmission causing this. Low resistance = high voltage = code 4627 Overcurrent, A-High Solenoid Circuit...or so is my thinking. If some people would be kind enough to do the solenoid ohm test and report their findings I'm sure that would help me and future people with this issue.