350TacoZilla

Member

- 263

- 1

- 16

- Location

- Hancock MD

ahh didnt know that about the 14.5's or 365's, seems to me 22.5's would be easier since it wouldn't require any type of wheel modifications.

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Looking at an an M35A3 rim and looking at a 10lug 5ton rim, it looks to me like it'd need recentering.I still have this question....can the M35A3 (metric) wheel be drilled for 10 lug use on a 5 ton or does it have to be re-centered?

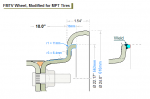

1) The diameter of the flat surface on the inside seems to be 13.5", which would be acceptable for a typical 5-ton hub. (You will have to confirm both dimensions since I don't have either one at hand, here.)I still have this question....can the M35A3 (metric) wheel be drilled for 10 lug use on a 5 ton or does it have to be re-centered?

None that I know of...............

Just to confirm, there isn't another 20" metric rim that fits the 5 ton 11.25 bc, is there? How would you get the 14.5 on a 5 ton?

![20180920_155926 [HDTV (720)].jpg 20180920_155926 [HDTV (720)].jpg](https://www.steelsoldiers.com/data/attachments/524/524028-1e3642de4d70ebeb88241939a34ed148.jpg)

Yes, cut a slice off of the original lip (~7mm wide), cut that ring open, slightly curved it to the lesser diameter and then just tack-welded in place after shortened. Create a nice deep welding groove on the inner side, then the same on the outer, making sure you get 100% penetration. Not difficult at all if you have adequate tools.Nice job on welding. How did you make the piece that was welded on? Was it part of what you cut off, cut down?

Not really.Did you get any heat distortion?

Correct; the original wheel is- or should be an 8mm radius. And since for the MPT, d2 is a tad smaller too (1.6mm), it allows one to remove some material at the high spots and greatly reduce the possible run-out, that way.I thought R3 was different too.

Yes, of course.Could the same modification be made to a combat wheel that already has the right bolt circle?

Well, it takes some time and patience, but the results are worth it. As you can see in this short video...That looks like a lot of work x2 (both sides).