-

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

GM-7 Turbocharger

- Thread starter jim1131

- Start date

More options

Who Replied?- 24

- 40

- 13

- Location

- Bostic, NC

The GM7 actuator is spring controlled (used on Military HMMWV only), so no vacuum port.

The GM6 is basically the same (rear/center mount) turbo as the GM7 but GM6 has a vacuum actuator for the waste-gate.

GM6 was used on the civilian H1's and GM turbo vans that had a computer controlling fuel and boost, GM7 is all mechanical, self-contained boost control.

The GM6 is basically the same (rear/center mount) turbo as the GM7 but GM6 has a vacuum actuator for the waste-gate.

GM6 was used on the civilian H1's and GM turbo vans that had a computer controlling fuel and boost, GM7 is all mechanical, self-contained boost control.

Thank you for explaining it.The GM7 actuator is spring controlled (used on Military HMMWV only), so no vacuum port.

The GM6 is basically the same (rear/center mount) turbo as the GM7 but GM6 has a vacuum actuator for the waste-gate.

GM6 was used on the civilian H1's and GM turbo vans that had a computer controlling fuel and boost, GM7 is all mechanical, self-contained boost control.

- 802

- 916

- 93

- Location

- Bainbridge Island Wa

Curious what the waste-gate psi boost is set for on the ECV HMMWV. Looked around but did not see a definitive spec on boost regulation.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

- 7,558

- 10,601

- 113

- Location

- Papalote, TX

Turbomaster makes an adjustable wastegate controller for the GM7, of course this would not be recommended without an EGT and BOOST gauge.

It is said the factory stock turbo stalls between 14-15PSI, I put a high performance compressor wheel in the turbo going on my GEP turbo engine but do not plan any other mods at this time, other than the EGT and BOOST gauges of course!!

They say stall but what actually happens is what we call a surge in the gas compressor business, the compressor impeller gets to a point where it can no longer sustain the pressure differential across the compressor and the compressor quits "compressing" this can and does "unload" the turbine causing a RAPID rise in turbo shaft RPM, this can damage the bushings in the compressor as there is a definite limit to the RPM the shaft and bushings can tolerate. THEN as the pressure differential decreases across the compressor the compressor wheel "kicks" back in loading the compressor wheel causing much strain to the wheel and a rapid decrease in RPM.

I was involved in several tests on a 10KHP turbo natural gas compressor in the 80s, it is a real trip when they go into surge, the first hint is a rumbling kinda like on Jurassic Park then all hell brakes loose, but you have to know at different gas pressures and temperatures where the compressor surges so you can calibrate the PLC to keep it from happening while getting the maximum performance out of the compressor..

The idea of course was to catch it at the "rumbling" stage before it would actually surge but it happens so damn fast it is hard to throttle back the turbine in time.

One of the other techs and I would be measuring the up and down stream pressures with dead weights right at the compressor end of the turbine.

Like I said a real trip being that close to a turbine compressor that big with a 1000 PSI discharge when it surges, of course in reality we were in no more danger than anyone else at the station, if there had been a catastrophic failure we all would have been nothing more than dust in the wind..

EDIT,of course now days with advanced computer modeling these kinds of "tests" are no longer necessary, just before I retired in 2019 the company I worked for built the largest gas compressor station in the northern hemisphere, 120,000 HP pumping 2.5 BCF/day into a 48" line (.965" wall) at 2500 PSI, can't even hear the damn thing run 1/4 mile away, all the romance is gone.....

It is said the factory stock turbo stalls between 14-15PSI, I put a high performance compressor wheel in the turbo going on my GEP turbo engine but do not plan any other mods at this time, other than the EGT and BOOST gauges of course!!

They say stall but what actually happens is what we call a surge in the gas compressor business, the compressor impeller gets to a point where it can no longer sustain the pressure differential across the compressor and the compressor quits "compressing" this can and does "unload" the turbine causing a RAPID rise in turbo shaft RPM, this can damage the bushings in the compressor as there is a definite limit to the RPM the shaft and bushings can tolerate. THEN as the pressure differential decreases across the compressor the compressor wheel "kicks" back in loading the compressor wheel causing much strain to the wheel and a rapid decrease in RPM.

I was involved in several tests on a 10KHP turbo natural gas compressor in the 80s, it is a real trip when they go into surge, the first hint is a rumbling kinda like on Jurassic Park then all hell brakes loose, but you have to know at different gas pressures and temperatures where the compressor surges so you can calibrate the PLC to keep it from happening while getting the maximum performance out of the compressor..

The idea of course was to catch it at the "rumbling" stage before it would actually surge but it happens so damn fast it is hard to throttle back the turbine in time.

One of the other techs and I would be measuring the up and down stream pressures with dead weights right at the compressor end of the turbine.

Like I said a real trip being that close to a turbine compressor that big with a 1000 PSI discharge when it surges, of course in reality we were in no more danger than anyone else at the station, if there had been a catastrophic failure we all would have been nothing more than dust in the wind..

EDIT,of course now days with advanced computer modeling these kinds of "tests" are no longer necessary, just before I retired in 2019 the company I worked for built the largest gas compressor station in the northern hemisphere, 120,000 HP pumping 2.5 BCF/day into a 48" line (.965" wall) at 2500 PSI, can't even hear the damn thing run 1/4 mile away, all the romance is gone.....

Last edited:

MattNC

Well-known member

- 222

- 271

- 63

- Location

- Raleigh, NC

Mogman, where do you look to for high performance compressor wheels? I am putting in a rotomaster-sourced one next week which was an OEM one for GM 6.5's and will stay stock at least for a while, but curious what performance ones are out there that may spool up a bit faster.

Thanks

Thanks

- 7,558

- 10,601

- 113

- Location

- Papalote, TX

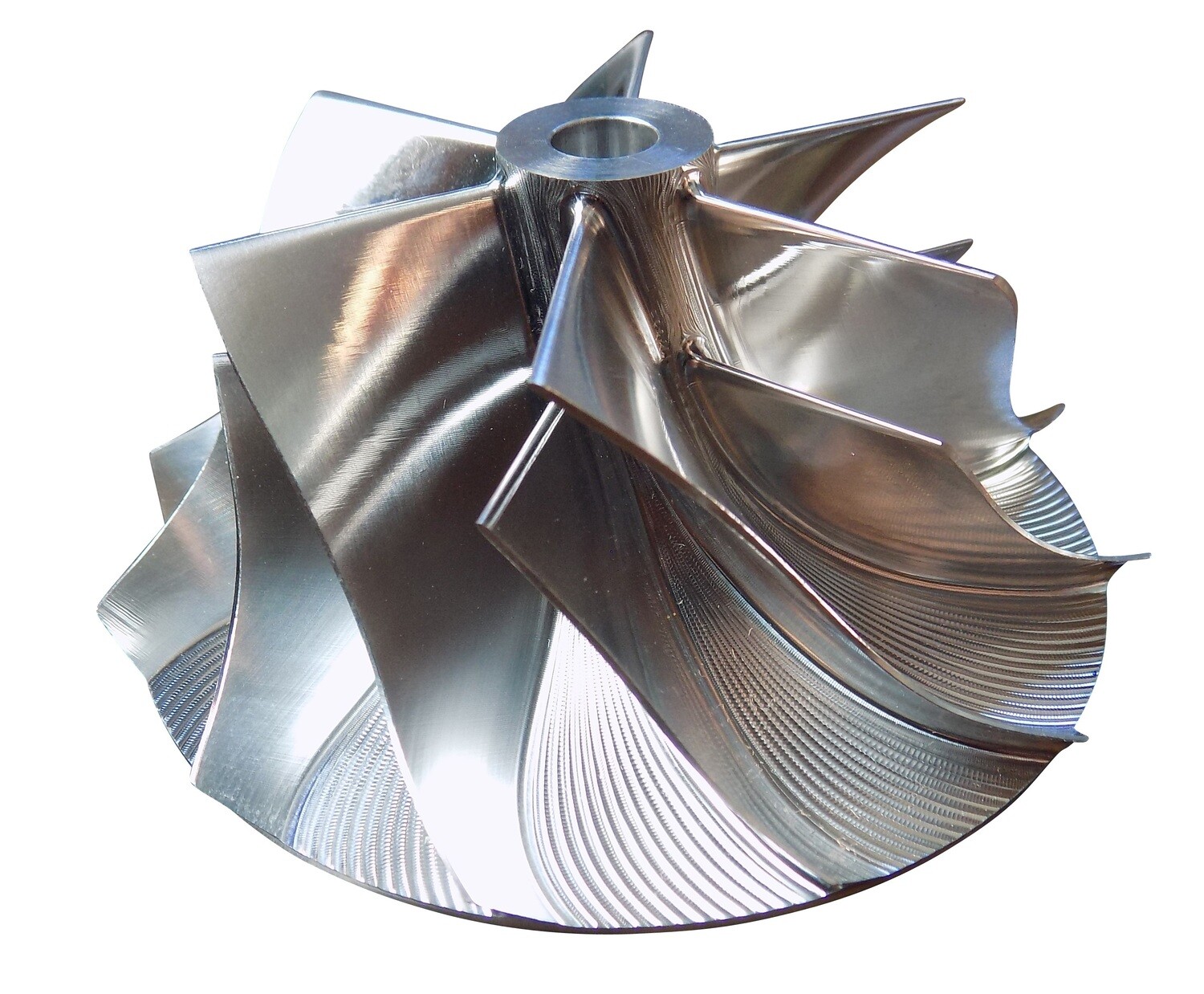

Extended Tip Billet Compressor Wheel for 6.5l Chevy GMC Turbo Diesel 1992-2002

Extended Tip Billet Compressor Wheel for 6.5l GM3/GM4/GM5/GM6/GM7/GM8 Turbos. Inducer: 51.9mm Exducer: 70.0mm 6/6 Blade Design for All Around Performance Pre Balanced Fits: 1992-2002 Chevy/GMC C/K 1500/2500/3500 Trucks, Blazers & Suburbans with the 6.5l turbo diesel.

kbdieselperformance.com

kbdieselperformance.com

- 7,558

- 10,601

- 113

- Location

- Papalote, TX

IMHO not worth the effort

A bit late but I must add a correction about surge and stall. They are too separate conditions.

Surge is a lack of flow through the compressor wheel. The compressor needs flow to create a load and keep it from overspending. A clogged air filter can cause surge.

Stall is a lack of flow through the exhaust. There isn't enough power to keep the compressor spinning fast enough to overcome the pressure in the intake manifold. Under stall, air from the pressurized intake manifold flows backwards through the turbo towards the air filter. This can be caused by chopping the throttle while under boost. It's sometimes referred to as turbo bark.

This was a good demonstration of compressor stall on a very large turbo:

Surge is a lack of flow through the compressor wheel. The compressor needs flow to create a load and keep it from overspending. A clogged air filter can cause surge.

Stall is a lack of flow through the exhaust. There isn't enough power to keep the compressor spinning fast enough to overcome the pressure in the intake manifold. Under stall, air from the pressurized intake manifold flows backwards through the turbo towards the air filter. This can be caused by chopping the throttle while under boost. It's sometimes referred to as turbo bark.

This was a good demonstration of compressor stall on a very large turbo:

Last edited:

- 7,558

- 10,601

- 113

- Location

- Papalote, TX

A compressor stall is a local disruption of the airflow in the compressor of a turbocharger. A stall that results in the complete disruption of the airflow through the compressor is referred to as a compressor surge.

- 114,391members

- 167,274threads

- 2,354,809posts

- 3,628online users