CallMeColt

Well-known member

- 1,153

- 1,724

- 113

- Location

- Wilson County, Texas

Well, I had a setback on this thing that keeps snowballing!

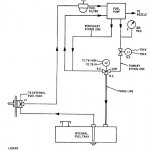

It started to leak fuel between the two solenoids. Of course, the way it is plumbed, it is at a super hard to get place and you need to disconnect almost everything to tighten it. Did all that, but in the process, the brass nipple coming off the fuel pump broke off in the pump!

I luckily managed to get that out. My plan was to mount the solenoids on the wall where the fuel fill area is so they're more accessible and use new 4AN stainless lines. Ordered a bunch of stuff.

As I was working along, while tightening, I broke the small fuel solenoid! Ordered one but turned out it was incorrect. All very frustrating!

I just want to get the unit back together and running properly again, then I will probably sell/trade it. It is to much for my needs. I need a smaller unit & they have them out there.

It started to leak fuel between the two solenoids. Of course, the way it is plumbed, it is at a super hard to get place and you need to disconnect almost everything to tighten it. Did all that, but in the process, the brass nipple coming off the fuel pump broke off in the pump!

I luckily managed to get that out. My plan was to mount the solenoids on the wall where the fuel fill area is so they're more accessible and use new 4AN stainless lines. Ordered a bunch of stuff.

As I was working along, while tightening, I broke the small fuel solenoid! Ordered one but turned out it was incorrect. All very frustrating!

I just want to get the unit back together and running properly again, then I will probably sell/trade it. It is to much for my needs. I need a smaller unit & they have them out there.