Ronmar

Well-known member

- 4,479

- 8,393

- 113

- Location

- Port angeles wa

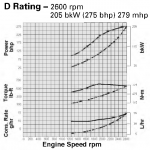

Is the mog an automatic?So, after reading the Eco Direct post…0.78x3.07x450 rev/mile = 1078 engine rpm at 60 mph in 7th…

It might get rolling decently using 1st all the time.

I think Caterpillar might not approve of running the vehicle up against air resistance max speed at that low rpm might be called lugging, although if allowed to the transmission would find a half decent gear. Maybe 5 or 6 depending on load.

Wouldn’t want to change hubs in the middle of a trip in a dirty environment.

Cheaper? Yes.

People who spend $120-170k on an Acela + many $100ks more on a fancy camper box wouldn’t go for it.

But it’s an interesting idea. It might, maybe, pull 7th with 3.9s empty.

3.04 final gearing. My Mog (similar weight and powerplant and air resistance and tires) has 4.36 final gearing in 8th.

Remember this truck was not built for a commercial application. It was built to meet a MILSPEC. In the land of milspec, often serious compromises are acceptable, and often not even looked for/tested… A prime example of this on this same platform, is the grossly mismatched alternator to battery bank. Someone specced X amount of CCA but didn’t spec an appropriate amount of charging capacity to properly support it. The 2:1 hubs were probably chosen to help the package meet just such a specification. And unless you are only using the truck to perform those specified task(surmount an 18” curb at 26,000 pounds?), they may create compromises in other areas.