- 7,527

- 10,564

- 113

- Location

- Papalote, TX

One thing to remember is once a belt is damaged in any way it will continue to jump grooves whether the pulleys are correctly aligned and all the bearings are good or not.

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Okay I believe I found the problem.What version of serpentine do you have? Post a pic…

it doesn’t take much for jump off to occur…I’ve dealt with this numerous times with varying reason for it, but all obviously an alignment issue not visible to the naked eye. The one I fixed last week was the Generator/PS bracket was held on with 1 bolt, 1 broken bolt still in the head and 1 missing bolt. The week before that, all 3 bolts on a truck were finger loose, you could see the generator moving way to much while at idle.

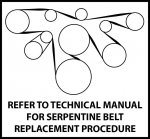

No, but the drawings to build a pullet alignment tool is.Super interesting. I bet this is NOT in the TM’s.

Nice detective work sir.

The pulley was bent inward, shortening length of required belt and putting the Sanden pulley out of alignment or square w the rest of the pulleys - just barely.If the bracket is bent, doesn't that also mean it's no longer square to the rest of the pulleys?

Why does that pulley look wider than the belt ? And have more and skinnier grooves than the belts ribs?The pulley was bent inward, shortening length of required belt and putting the Sanden pulley out of alignment or square w the rest of the pulleys - just barely.

ALSO - SUCCESS!!

Two washers in two of the upper mounting points, pushing the Sanden rearward. Two washers roughly = 1 rib.

View attachment 859656

I loosened all mounting bolts, removed the two upper bolts, inserted 2x washers/ea then retightened.

As you can see before the fix, the pulley alignment was, visibly, almost perfect. Just BARELY off - when using a laser. The pic isn’t the best, but you can see nonetheless, the belt has climbed one rib.

View attachment 859657

So far, it’s be idling for 20 min w and w/out AC engaged. No change. Looks solid so far!

Will keep the thread updated.

Possibly bad picture? I assure you it’s correct.Why does that pulley look wider than the belt ? And have more and skinnier grooves than the belts ribs?

on my truck it once appeared that the power steering pump was out of alignment.I have been dealing with the same with belts jumping then failing. I had my water pump and harmonic balancer crap out as well, both needed to be replaced. What I see on mine is that the power steering pump is to far forward. The AC condenser is about a half grove off.

Anyone else see alinement issues with thier power steering pump?

The condenser has a belt?I have been dealing with the same with belts jumping then failing. I had my water pump and harmonic balancer crap out as well, both needed to be replaced. What I see on mine is that the power steering pump is to far forward. The AC condenser is about a half grove off.

Anyone else see alinement issues with thier power steering pump?

*compressor lolThe condenser has a belt?

even with the stud/nut still sitting there, the stud itself can shear between the manifold and that nut.It would be hard to bend a bracket for the AC compressor. The alternator and power steering bracket is cast so it would on crack.

I checked all my brackets and everything seems secure. The attached picture is the alternator bracket bolted to the manifold. it seem there is a washer and nut to hold on the exhaust manifold and then the alternator bracket which is washer and bolted. Does this look like everyones truck? Any recommenation on how to adjust the power steering pump?

I did not realize the power steering and alternator use the same bracket.