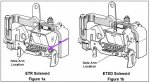

It does appear our systems have the triangular piece that would allow using ETSO solenoid. Pics below.

Here are some pics from a thread discussing this mechanism. Credit of the pics to this thread linked here.

Pic 1: solenoid with the lever in 'non running' position. Solenoid would be 'off' here. The lever is pushing the fuel cutoff lever into 'off' position by pushing the arm towards the rear of the housing (right side of picture).

Pic 2: shows the solenoid with the lever in 'running' position. Solenoid is 'on' and energized and is pulling the lever arm back into the housing. This allows the fuel cutoff arm to go towards front of housing (left side of picture). This allows fuel into the IP.

Pic 3: The fuel cutoff mechanism is visible here (upper part pic in housing at floor). This has a spring which by default keeps it 'pushed' toward the front of the housing (left side of pic). Towards the rear of the housing (right side of pic at floor) you can see a pivot mechanism that directly cuts off the fuel as "8" described. When the solenoid is "on" and energized it pulls the lever arm of the solenoid towards the solenoid which allows the arm of the fuel cutoff mechanism to go towards the front of the housing and engaging the pivot arm to 'open' the fuel to the IP.

Pic 4: When the solenoid is "off" there is a spring on the solenoid that keeps the lever arm out from the solenoid and pushes the arm of the fuel cutoff mechanism towards the rear of the housing (towards right side of pic). This engages the pivot arm into a fuel "off" position for the IP. The finger in the picture is essentially acting like the de-energized solenoid lever arm and pushing the mechanism towards the rear of the housing (towards right side of pic).

In the third pic towards the upper left of housing you can see the triangular part coming off the mechanism that the ETSO solenoid would engage. This would essentially be in the reverse of what was just desribed.