galaxie428

Active member

- 235

- 107

- 43

- Location

- Rushville, IN

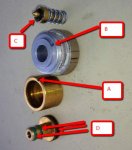

A few weeks ago, my shutter stat started leaking air out of the little pin hole. I replaced the two smaller orings and the larger black one this week. I took it out for a drive and it seemed to work or at least it didn't leak air. The truck never gets over 160 with normal driving to I thought everything was fine until my trip to Haspin for the rally today.

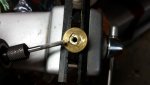

We took to the trails and the truck was doing fine until one of the larger hills, the temp went up according to the gauge to about 200. After the second hill I was about 220 so I headed back to camp to let the truck cool because the fan never came on. When I raised the hood, I noticed that the plunger on the shutter stat was sticking out the back about 1/4". After sitting for a while, the plunger went back in but then it started leaking air, this time not out the little pin hole but around the plunger.

We took the shutter stat apart again, re-lubed the rings and tried the trails again. Same thing happened.

So how does this thing work? What is causing the problem? What are the parts supposed to be doing?

Any help explaining this would be appreciated to help me figure out how to fix it.

We took to the trails and the truck was doing fine until one of the larger hills, the temp went up according to the gauge to about 200. After the second hill I was about 220 so I headed back to camp to let the truck cool because the fan never came on. When I raised the hood, I noticed that the plunger on the shutter stat was sticking out the back about 1/4". After sitting for a while, the plunger went back in but then it started leaking air, this time not out the little pin hole but around the plunger.

We took the shutter stat apart again, re-lubed the rings and tried the trails again. Same thing happened.

So how does this thing work? What is causing the problem? What are the parts supposed to be doing?

Any help explaining this would be appreciated to help me figure out how to fix it.