Connector list that matches the factory Ibis Tek wiring harness, at least for my 66" one:

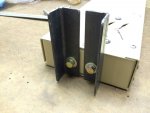

Power Plug:

Male plug:

Delphi, P/N: 12129939-B

Automotive Connectors CON MP 630 2W FEM

http://www.mouser.com/Search/Produc...9-Bvirtualkey63000000virtualkey829-12129939-B

Female pins for the above male power plug:

**Note: There are multiple terminal options depending on the size of the wire used. These fit 12 gauge wire very tightly, or two 16 gauge prestolite wires for split connections.

Delphi, P/N: 12084590-L

Automotive Connectors FMALE 630 SERIES TIN CBL RANG 5.24-3.49MM

http://www.mouser.com/Search/ProductDetail.aspx?R=12084590-Lvirtualkey63000000virtualkey829-12084590

Female plug:

Delphi, P/N: 12129938-B

Automotive Connectors CON MP 630 2W ML

http://www.mouser.com/Search/Produc...8-Bvirtualkey63000000virtualkey829-12129938-B

Male pins for the above female power plug:

**Note: There are multiple terminal options depending on the size of the wire used. These fit 12 gauge wire very tightly, or two 16 gauge prestolite wires for split connections.

Delphi, P/N: 12066493-L

Automotive Connectors TERM M/P 630 ML

http://www.mouser.com/Search/Produc...3-Lvirtualkey63000000virtualkey829-12066493-L

Connector lock for both the above male and female plugs:

Delphi, P/N: 12129940-B

Automotive Connectors TPA BLU SCNDRY LK

http://www.mouser.com/Search/Produc...0-Bvirtualkey63000000virtualkey829-12129940-B

Rear Control:

Rear Control:

See Delphi's Metri-Pack 150 for a complete listing and alternate terminal options for different gauge wire.

21.8 MB PDF:

http://ecat.delphi.com/docs/default-source/ecatalog-documents/metri_pack_series_section-pdf.pdf

View attachment metri_pack_series_section-pdf.pdf

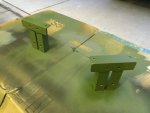

Male plug for rear control:

Delphi, P/N: 12047781-B

Automotive Connectors CON MP 150 3W FEM

http://www.mouser.com/Search/Produc...1-Bvirtualkey63000000virtualkey829-12047781-B

Female pins for the above rear control male plug:

**Note: There are multiple terminal options depending on the size of the wire used. These fit 20-22 gauge wire fine.

Delphi, P/N: 12047767-L

Automotive Connectors FMALE 150 SERIES TIN CBL RANG 2.40-1.70MM

http://www.mouser.com/Search/ProductDetail.aspx?R=12047767-Lvirtualkey63000000virtualkey829-12047767

Connector lock for the above rear control male plug:

Delphi, P/N: 12047783-B

Automotive Connectors TPA M/P 150 LK

http://www.mouser.com/Search/Produc...3-Bvirtualkey63000000virtualkey829-12047783-B

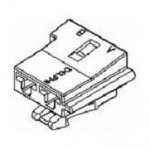

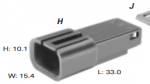

Female Plug for the rear control:

Delphi, P/N: 12047782

Automotive Connectors 3P MALE BLACK 150 SERIES 14 AMPS

http://www.mouser.com/Search/ProductDetail.aspx?R=12047782virtualkey63000000virtualkey829-12047782

(Note: At the time of this writing, the picture in the above link is actually just the generic Metri-pack 150 unsealed connector image, see the below, correct, reference picture)

Male pins for the above rear control female plug:

**Note: There are multiple terminal options depending on the size of the cable used. These fit 20-22 gauge wire fine.

Delphi, P/N: 12059894-L

Automotive Connectors MALE 150 SERIES TIN CBL RANG 2.40-1.47MM

http://www.mouser.com/Search/Produc...4-Lvirtualkey63000000virtualkey829-12059894-L

Connector lock for the above rear control female plug:

Delphi, P/N: 12047784-B

Automotive Connectors TPA MP 150 3W LK

http://www.mouser.com/Search/Produc...4-Bvirtualkey63000000virtualkey829-12047784-B

Front Control:

Front Control:

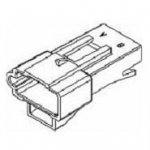

Female plug:

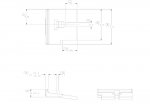

Delphi, P/N: 12064763-B

Automotive Connectors CON MP 150 6W ML

http://www.mouser.com/Search/Produc...3-Bvirtualkey63000000virtualkey829-12064763-B

Male pins for the above front control female plug:

**See the male pins for the rear control plug, I believe they're the same.

Connector lock for the above front control female plug

Delphi, P/N: 12064765-B

Automotive Connectors TPA M/P 150 LK

http://www.mouser.com/search/ProductDetail.aspx?R=0virtualkey0virtualkey12064765-B

Front Control male plug:

Delphi, P/N: 12064762-B

Automotive Connectors CON MP 150 6W FEM

http://www.mouser.com/search/ProductDetail.aspx?R=0virtualkey0virtualkey12064762-B

Female pins for the above front control male plug:

**See the female pins for the rear control plug, I believe they're the same.

Connector lock for the above front control male plug:

**Note: Requires

two

Delphi, P/N: 12064764-B

Automotive Connectors TPA M/P 150 LK

http://www.mouser.com/search/ProductDetail.aspx?R=0virtualkey0virtualkey12064764-B