- 1,967

- 1,297

- 113

- Location

- Paris KY

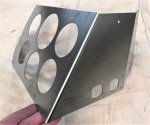

Made a little more progress today. Got the GM14020856 brace rod installed between the NP241 and the P400 engine block. Also installed the bracket for the new transfer case cable shifter from JB Custom Fabrication https://jb-custom-fabrication.myshopify.com/collections/cable-shifters-cable-shifter-components . The cable shifter will replace the OEM shifter and linkage which would be difficult to access after the new gauge cluster has been installed. The new cable shifter lever and boot will be installed in the flat floor space to the right of the drivers seat for easy operation without having to reach across the transmission tunnel. Already worked through the engineering and confirmed that everything will fit without any issues.