Kaiser67M715

Member

- 699

- 26

- 18

- Location

- NH

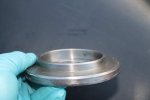

So, went about getting my knuckles all put together, cleaned and inspected everything, installed the spindle, hub backing plate, and all of a sudden, no movement, can't turn the knuckle, can't even spin the axle.

??

Well tore it all back down(and realized that my "grade 8" nuts I bought are probably just grade 5 or less, stripped a couple, bottoms are all tore up from the lock washers) but as soon as the spindle got just a little loose, everthing rotated as it should, so slowly re-tightened everything, seems to be going fine, right till my final torque, no movement.

Now I know I got to tear it all down(and replace all the nuts) but I am wondering if any of you all have an idea as to what could be going on? any specific areas I should keep an eye out for?

**I have only done passenger side, figure if it happens on one side, may happen on the other, much rather try to only assemble things once

??

Well tore it all back down(and realized that my "grade 8" nuts I bought are probably just grade 5 or less, stripped a couple, bottoms are all tore up from the lock washers) but as soon as the spindle got just a little loose, everthing rotated as it should, so slowly re-tightened everything, seems to be going fine, right till my final torque, no movement.

Now I know I got to tear it all down(and replace all the nuts) but I am wondering if any of you all have an idea as to what could be going on? any specific areas I should keep an eye out for?

**I have only done passenger side, figure if it happens on one side, may happen on the other, much rather try to only assemble things once