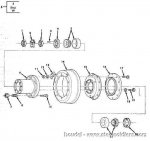

Well,if your going to do seals and everything you might as well do both sides.You will need 2 axle tube seals(only used on the front axle) and 2 inner seals.A small bucket of GAA or Equivilent grease(standard Yellow bearing Grease),a 8 foot peice of 1" pipe to knock out the inner axle tube seals,Big Hammer,one wheel cylinder per side(only one Wheel Cylinder per wheel front or rear),plenty of rags and cleaner,Big freaking Jack stands or I like to use Railroad ties cut down into 18-24" sections,Some Smurf snot(RTV) to reseal the Hub drive flange,and if you get down and dirty and plan every move you can do this job in a day Easy.Just jack the truck up and put the cribbing/stands under it.Remove the wheels(Make sure you break them loose before jacking up the truck),Not pull the drive flange in the center of the drum.Remove the outter nut behind it,then the tabbed lock washer,now the inner,Pull the drum out about an inch and push it back,Pull the outter bearing.Now pull the drum entirely off and be careful NOT DO DROP IT ON YOUR FOOT!!!To get to the seals you gotta remove the brake shoe spring on top to get to all the bolts holding the brake backing plate and spindle to the knuckle.Remove them and save the star washer(Good idea to just get new ones,They are cheap).Pull the brake backing plate off and hang it on the frame with a piece of wire.Get a rubber hammer and give the spindle a few good love taps and it should pull right off.Inside you will see the most ungodly smelling goo which will be old grease and axle oil mixed.With the spindle off you can grab the axle and give it a yank.It will come right out.Now repeat for the other side.Once everything is apart,take the 8 foot pipe and run it though one side though the center section and feel for the seal and retainer.Once your on it hit the pipe a couple HARD hits and the retainer should just pop out.Go to the other side(just push the pipe in and grab the other end on teh other side and repeat.Knock the old seal outta the retainer and use a big socket to tap the new seal into both holders.Clean up the knuckle area of all old greaseNow use a large diameter peice of pipe or other object slightly smaller than the OD of the retainer to knock it back into the axle housing.Now clean the axles up real good and apply a good amount of grease to the U joint area and a thin coating of grease to the knuckle area.Slide the axle back in.Take the spindles and pry the old seal off and use a peice of pipe just larger than teh ID of the seal(I got lucky and had a peice of really big Conduit I got out of the scrap hopper at work that did both the retainers and the spindle seals) and drive the new seal onto the step.You might have to use a flat nose punch or screwdriver to finish knocking it all the way on.Now reinstall the spindle,the backing plate,the big round thingy and all the star washers and nuts.Be careful,The studs are soft and can break easy or strip.Now you can remove the bad wheel cylinder or Cylinders.Just remove the big Banjo bolt on the back and some how keep it elevated or all the brake fluid will drain out(EXPENSIVE brake fluid!).Pull the 2 bolts and push one op rod in enough to clear the brake shoe.Reinstall the new cylinder if your brake shoes look good........ok,my fingers are numb.someone else take over from here.