Ridgerunner

New member

- 791

- 6

- 0

- Location

- Holland, Mi

I bobbed my deuce last spring, and I had bought a set of 53" XZL's towards the end of last summer. The tires have just been sitting in my barn doing nothing, other than collecting dust and taking up space.

So this week I started to make the lift so the 53's will fit on the Deuce. It'll be lifted a total of 8 inches when finished, which should provide plenty of clearance, without any worries about the tires rubbing the fenders or J-pipe. I'm making it so it will be a complete bolt on "kit", that way if I don't like it, or want to remove it for some reason, it can be unbolted and then the original brackets/hangers can be reinstalled back to stock.

The drop brackets consist of 2 1/2"x 3/8" flat, 3x3"x 3/8" angle and 3/8" plate for the sides. 10 bolts will hold the drop brackets to the frame, using six of the original bolt/rivet locations. The very front, and far rear drop brackets will be connected across together with 1/4" plate bent at 70 degrees, so it'll bolt to the brackets and under the frame. In the front I designed it so the cross member plate will use the exsisting winch extention bolts under the frame.

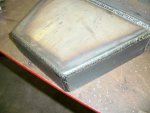

This is what I built today so far.

So this week I started to make the lift so the 53's will fit on the Deuce. It'll be lifted a total of 8 inches when finished, which should provide plenty of clearance, without any worries about the tires rubbing the fenders or J-pipe. I'm making it so it will be a complete bolt on "kit", that way if I don't like it, or want to remove it for some reason, it can be unbolted and then the original brackets/hangers can be reinstalled back to stock.

The drop brackets consist of 2 1/2"x 3/8" flat, 3x3"x 3/8" angle and 3/8" plate for the sides. 10 bolts will hold the drop brackets to the frame, using six of the original bolt/rivet locations. The very front, and far rear drop brackets will be connected across together with 1/4" plate bent at 70 degrees, so it'll bolt to the brackets and under the frame. In the front I designed it so the cross member plate will use the exsisting winch extention bolts under the frame.

This is what I built today so far.

Attachments

-

79.8 KB Views: 901

-

75.3 KB Views: 919

-

87.2 KB Views: 1,001

-

86.2 KB Views: 1,129

-

86.4 KB Views: 1,187

-

91.7 KB Views: 1,114

-

81.1 KB Views: 1,173

-

94.1 KB Views: 994