- 2,958

- 28

- 48

- Location

- Tiro, Ohio

I've never been happy with the 3 lever switches. Seems like they like to pop the circuit breaker at the worst times, leaving me without lights. Usually when I am towing at night on an interstate with the flashers on. Not a fun time.

I've tried about 4 switches so far and they still pop, no matter what truck I am using. I think the breakers get weak. Even carry spares. In defense of the switches, none of them are new, usually I get them at swap meets, probably after someone else abused them.

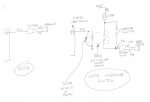

So I decided to take apart the switches and remove/jumper the breakers. Then I am installing a inline fuse holder with a breaker in the harness. I can use fuses also, and don't have to replace the switch when the breaker goes bad. Also going to use a current meter and see what kind of amps I am using.

I took apart 4 light switches. 2 were almost identical, one was similar, and the last one was completely different. Here is a pic of the 2 styles I was dealing with. 3 out of 4 breakers had melted contacts.

Also a pic of the fuse holder with breaker, and a circuit breaker from inside the switch. Only one switch had a removable breaker.

I've tried about 4 switches so far and they still pop, no matter what truck I am using. I think the breakers get weak. Even carry spares. In defense of the switches, none of them are new, usually I get them at swap meets, probably after someone else abused them.

So I decided to take apart the switches and remove/jumper the breakers. Then I am installing a inline fuse holder with a breaker in the harness. I can use fuses also, and don't have to replace the switch when the breaker goes bad. Also going to use a current meter and see what kind of amps I am using.

I took apart 4 light switches. 2 were almost identical, one was similar, and the last one was completely different. Here is a pic of the 2 styles I was dealing with. 3 out of 4 breakers had melted contacts.

Also a pic of the fuse holder with breaker, and a circuit breaker from inside the switch. Only one switch had a removable breaker.

Attachments

-

72.7 KB Views: 49

-

59.4 KB Views: 43

-

26.7 KB Views: 45

-

61.7 KB Views: 51

-

74.4 KB Views: 37

-

51.8 KB Views: 39

Last edited: