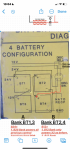

Please tell me more about the 3rd pic, the altered battery box diagram… yours isn’t wired like this is it?

What I have observed playing with my 100A Neihoff is that it is configured as a battery balancer. It is looking for a 12v connection INTO THE MIDDLE of a 24v series battery string. When it does not see that connection, mine does not operate properly… as I recall it pulsed/cycled looking for that relationship, because any change on a voltage fed to the 12 or 24v point in a series string will effect the other voltage. When it does not see this interaction it resets. As I recall it also derated the 28v output. Let me see if I can dig up where I wrote about it, was a long while back…

if yours are wired like that altered diagram, you have 1. Removed that 12 from the middle of 24. 2. Created two vastly different size battery banks(24v@120AH, and 12V@240AH), that would be impossible to balance anyway, even if they were connected in a fashion that satisfied need number 1.

if wired like that, I would not expect a dual volt Neihoff to operate properly…

if you are wired like that, a quick check would be to disconnect the red lead in the drawing where it connects to BT4+, and connect it to either BT3+ or BT1-. That would connect the 12v alt output to the middle of 2 equal size batteries in series as Neihoff designed it…

whatever the size of your batteries, it should be wired like this and ONLY like this…

View attachment 916789