Hey guys,

I've been following the threads on this site for the better part of the last six months, and it has been amazingly helpful! I have been applying advice from the site and have finally gotten to the point to try to get my m1008 project running. Let me run through a quick recap of what I've tried so far:

1) 12v roscommon conversion

2) doghead relay conversion

3) airtex electric fuel pump with spin on fuel filter (before pump and below fuel tank, mech pump gone)

4) push button manual gp override

5) ac60g's

6) drained fuel tank and put in new diesel

7) new 800cca batteries

I started by running the electric pump, doing a 6 second manual warm of the gp's and turned her over with no luck.

I then cracked the fuel line to make sure I was getting diesel to the pump, which I was.

Then I pulled the glowplugs and put a piece of cardboard in front of the holes and only one was getting anything out of it.

So I cracked the injectors and turned over the truck, they started weeping fuel.

Closed them back up again.

Still no luck...

Read some more... realized I needed to depress the throttle to halfway according to the service manuals, and as per recommendations fully until the lines were bled.

Also read that the ac60g's heat up more slowly and are safe to cycle in larger increments...

Held down the throttle to the floor and ran the gp's for 7 seconds, wait 5 seconds, then another 5. Turned the key and she would catch but not stay running.

Slept on it, read some more about replacing the return line with clear line (done) and pulling the top of the injector pump off to see if there is an obstruction....

Did this... there was no obstruction and fuel flows fine... more on this in a second. Not sure exactly what I was looking at nor that I put the top on correctly... looks like its supposed to go towards the radiator before pushing down towards the cab...

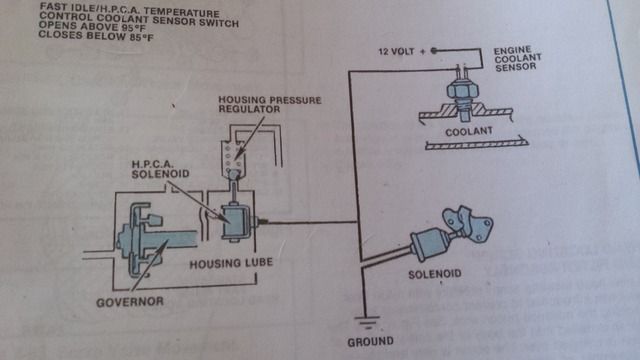

Put back together and no leaks... not sure the cold advance solenoid is working, and not sure there is a glass ball in the return line...

There is _no_ cold throttle advance solenoid... not sure if the 84 m1008 came with them?

At any rate, jumped in the cab, ran the ac60's for 10 seconds, let cool for 5 then 5 more seconds. Pushed throttle halfway to the floor and she runs.... kind of.

If I let off the throttle she dies.

If I move the throttle forward... she dies.

I don't have a tach on her, but it sounds like shes running 1500 or higher rpms...

Held her in the magic spot once long enough to get the engine somewhat warm and she sounded like she wanted to idle down... but died.

When running in the higher rpm state if I step on the throttle she does not accelerate.

You guys have been amazingly helpful from all the previous posts I have read and hopefully somebody has an idea.

The stuff I have in mind right now includes:

1) is the cold advance solenoid getting power?

2) if not is the thermostat sensor dead?

3) how about the position of the injector pump top... are their teeth that engage for the advance that I didn't get in right?

4) The timing marks are dead on... should I advance it slightly to the drivers side?... about 1mm from what Ive read

Dont know if there could be something else horribly wrong or not... now that I've got the starting process I can barely touch the key and it will try to catch and run... 7-10 seconds, let rest 5 seconds, then apply another 5 seconds of heat (only do this once...) then half gas and touch the key... vroom... just too much vroom.... and no control. Injectors? IP? Lines? Will keep working it, but if anybody has tips please let me know!

I've been following the threads on this site for the better part of the last six months, and it has been amazingly helpful! I have been applying advice from the site and have finally gotten to the point to try to get my m1008 project running. Let me run through a quick recap of what I've tried so far:

1) 12v roscommon conversion

2) doghead relay conversion

3) airtex electric fuel pump with spin on fuel filter (before pump and below fuel tank, mech pump gone)

4) push button manual gp override

5) ac60g's

6) drained fuel tank and put in new diesel

7) new 800cca batteries

I started by running the electric pump, doing a 6 second manual warm of the gp's and turned her over with no luck.

I then cracked the fuel line to make sure I was getting diesel to the pump, which I was.

Then I pulled the glowplugs and put a piece of cardboard in front of the holes and only one was getting anything out of it.

So I cracked the injectors and turned over the truck, they started weeping fuel.

Closed them back up again.

Still no luck...

Read some more... realized I needed to depress the throttle to halfway according to the service manuals, and as per recommendations fully until the lines were bled.

Also read that the ac60g's heat up more slowly and are safe to cycle in larger increments...

Held down the throttle to the floor and ran the gp's for 7 seconds, wait 5 seconds, then another 5. Turned the key and she would catch but not stay running.

Slept on it, read some more about replacing the return line with clear line (done) and pulling the top of the injector pump off to see if there is an obstruction....

Did this... there was no obstruction and fuel flows fine... more on this in a second. Not sure exactly what I was looking at nor that I put the top on correctly... looks like its supposed to go towards the radiator before pushing down towards the cab...

Put back together and no leaks... not sure the cold advance solenoid is working, and not sure there is a glass ball in the return line...

There is _no_ cold throttle advance solenoid... not sure if the 84 m1008 came with them?

At any rate, jumped in the cab, ran the ac60's for 10 seconds, let cool for 5 then 5 more seconds. Pushed throttle halfway to the floor and she runs.... kind of.

If I let off the throttle she dies.

If I move the throttle forward... she dies.

I don't have a tach on her, but it sounds like shes running 1500 or higher rpms...

Held her in the magic spot once long enough to get the engine somewhat warm and she sounded like she wanted to idle down... but died.

When running in the higher rpm state if I step on the throttle she does not accelerate.

You guys have been amazingly helpful from all the previous posts I have read and hopefully somebody has an idea.

The stuff I have in mind right now includes:

1) is the cold advance solenoid getting power?

2) if not is the thermostat sensor dead?

3) how about the position of the injector pump top... are their teeth that engage for the advance that I didn't get in right?

4) The timing marks are dead on... should I advance it slightly to the drivers side?... about 1mm from what Ive read

Dont know if there could be something else horribly wrong or not... now that I've got the starting process I can barely touch the key and it will try to catch and run... 7-10 seconds, let rest 5 seconds, then apply another 5 seconds of heat (only do this once...) then half gas and touch the key... vroom... just too much vroom.... and no control. Injectors? IP? Lines? Will keep working it, but if anybody has tips please let me know!