the test is to fully charge the system(dryer purges) then shutdown. drain all the air out of the wet tank and close the drain valve. Look for pressure drop on the pri/sec-rear/front air gauges in the dash. if you note air loss on the gauge, open the wet tank drain and if it has built up air, it is coming from the check on the tank that lost air pressure. if there is no pressure buildup in the wet tank, then the air is going somewhere else in the system after the service tanks.

Follow the line out of the wet tank to the service tanks, there is a check on each service tank input. disconnect the hose or hoses from the fitting on the check input port, and using 2 wrenches unscrew the inlet side of the check. it is sealed with an o-ring and has a metal star disc with rubber seal and a spring inside.

look for debris and corrosion inside and clean or replace as necessary. Old rubber, the valve probably just needs to be replaced like General said. They are not expensive...

surprisingly the only one i have found bad on my 98 so far is the one up near the front gladhand(pitted to hell), and that was when i was deleting it anyway. every other one i have pulled apart on my truck has been very clean and serviceable...

When clean put a little silicone GREASE on the cap O-ring, re-assemble the spring, disc and cap and re-attach the hose or hoses... Pressurize and leak check...

Just found one of these service input checks leaking on mine a few weeks ago. The person who assembled it used too much thread sealant on the NPT hose fitting and the buildup of gummy sealant had slowly migrated out onto the sealing surface to interfere with the sealing disc. cleaned right up and seals great now...

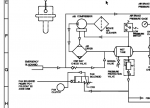

being an A0 your wet tank is probably plumbed incorrectly. 2 minute fix while you are under there, I can attach some pics when I get home this evening...