AmbitionStrikes

New member

- 10

- 6

- 3

- Location

- Sandpoint, ID

The truck: 1994 m1078

Condition: Has sat for several years, owner said the last time he drove it the brakes worked fine. Located in CA, temps are well above freezing.

Issue: When in gear the truck drives through the brakes, even at idle. If you engage the parking brake, it locks up and stops immediately. The brake pedal goes down to the floor with medium resistance. The air pressure gets up to 90+ psi and we can’t hear any leaks when holding the pedal (with the truck off so we can hear). Air pressure will hold overnight.

Diagnosis: Air was rushing out of the front emergency brake gladhandle. We took apart the check valve behind the bumper, cleaned it up (it was full of gunk) and upon reassembly no more air coming out.

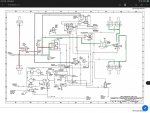

We downloaded the TM and followed the procedures in i2: Rear Brakes Do Not Apply. We couldn’t find any issues and it seems that air is being delivered through the system and to each wheel. We can visibly watch all 4 brakes being applied to the wheel when we press the pedal.

We didn’t have the correct tools to properly check the shoe spacing. But it did not appear excessive (also the owner assured us they worked last time it was driven). The diagnostics for Extended Braking Distance allude to issues with the brakes on a specific wheel, not the system as a whole so we are hesitant to start pulling drums off in the guys driveway.

Our latest guess is that maybe not enough air pressure is being delivered to the brakes?

It’s our first vehicle with air brakes and we’re trying to learn as much as possible. Any input is greatly appreciated!

Condition: Has sat for several years, owner said the last time he drove it the brakes worked fine. Located in CA, temps are well above freezing.

Issue: When in gear the truck drives through the brakes, even at idle. If you engage the parking brake, it locks up and stops immediately. The brake pedal goes down to the floor with medium resistance. The air pressure gets up to 90+ psi and we can’t hear any leaks when holding the pedal (with the truck off so we can hear). Air pressure will hold overnight.

Diagnosis: Air was rushing out of the front emergency brake gladhandle. We took apart the check valve behind the bumper, cleaned it up (it was full of gunk) and upon reassembly no more air coming out.

We downloaded the TM and followed the procedures in i2: Rear Brakes Do Not Apply. We couldn’t find any issues and it seems that air is being delivered through the system and to each wheel. We can visibly watch all 4 brakes being applied to the wheel when we press the pedal.

We didn’t have the correct tools to properly check the shoe spacing. But it did not appear excessive (also the owner assured us they worked last time it was driven). The diagnostics for Extended Braking Distance allude to issues with the brakes on a specific wheel, not the system as a whole so we are hesitant to start pulling drums off in the guys driveway.

Our latest guess is that maybe not enough air pressure is being delivered to the brakes?

It’s our first vehicle with air brakes and we’re trying to learn as much as possible. Any input is greatly appreciated!