- 1,672

- 897

- 113

- Location

- Central NY

Recent acquisition of former generator trailer - found mangled jack leg in the ground rod storage locker.

Nearly all of the individual components were bent, broke, distorted or combinations there of.

Bevel gear shaft was bent and distorted bushing housing on one side. Bigger hole was drilled to remove bevel gear locating pin. Cuts on either side were only way to remove bent shaft by cutting into 4.

Bevel gear shaft was bent and distorted bushing housing on one side. Bigger hole was drilled to remove bevel gear locating pin. Cuts on either side were only way to remove bent shaft by cutting into 4.

Bevel gear shaft bushing had to be warmed to straighten

Bevel gear shaft bushing had to be warmed to straighten

Pivot tab (attaches to trailer) was broken off and twisted. Too heavy to straighten on the thin upper leg section so offset V groove weld and ignored distortion on upper part.

Pivot tab (attaches to trailer) was broken off and twisted. Too heavy to straighten on the thin upper leg section so offset V groove weld and ignored distortion on upper part.

Retaining yoke for winding handle had been pushed in bending the thin wall upper leg section stopping the inner section from retracting all the way.

Retaining yoke for winding handle had been pushed in bending the thin wall upper leg section stopping the inner section from retracting all the way.

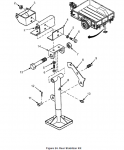

Layout of components

Layout of components

New bevel gear shaft next to old bent one cut into 4 to remove

New bevel gear shaft next to old bent one cut into 4 to remove

Lubed up and turned over - still need to find a handle or fab

Lubed up and turned over - still need to find a handle or fab  "Nut" that raises/lowers the lower section was broken into 7 parts. Fortunately cast steel can be welded. Two retaining pins already straightened

"Nut" that raises/lowers the lower section was broken into 7 parts. Fortunately cast steel can be welded. Two retaining pins already straightened

Repaired "nut" sitting in top of lower leg section

Repaired "nut" sitting in top of lower leg section

Threaded shaft had to be straightened - used bots in pin recesses so as not to damage repaired outer flanges.

Threaded shaft had to be straightened - used bots in pin recesses so as not to damage repaired outer flanges.

Nearly all of the individual components were bent, broke, distorted or combinations there of.

Bevel gear shaft was bent and distorted bushing housing on one side. Bigger hole was drilled to remove bevel gear locating pin. Cuts on either side were only way to remove bent shaft by cutting into 4.

Bevel gear shaft was bent and distorted bushing housing on one side. Bigger hole was drilled to remove bevel gear locating pin. Cuts on either side were only way to remove bent shaft by cutting into 4. Bevel gear shaft bushing had to be warmed to straighten

Bevel gear shaft bushing had to be warmed to straighten Pivot tab (attaches to trailer) was broken off and twisted. Too heavy to straighten on the thin upper leg section so offset V groove weld and ignored distortion on upper part.

Pivot tab (attaches to trailer) was broken off and twisted. Too heavy to straighten on the thin upper leg section so offset V groove weld and ignored distortion on upper part. Retaining yoke for winding handle had been pushed in bending the thin wall upper leg section stopping the inner section from retracting all the way.

Retaining yoke for winding handle had been pushed in bending the thin wall upper leg section stopping the inner section from retracting all the way. Layout of components

Layout of components New bevel gear shaft next to old bent one cut into 4 to remove

New bevel gear shaft next to old bent one cut into 4 to remove Lubed up and turned over - still need to find a handle or fab

Lubed up and turned over - still need to find a handle or fab  "Nut" that raises/lowers the lower section was broken into 7 parts. Fortunately cast steel can be welded. Two retaining pins already straightened

"Nut" that raises/lowers the lower section was broken into 7 parts. Fortunately cast steel can be welded. Two retaining pins already straightened Repaired "nut" sitting in top of lower leg section

Repaired "nut" sitting in top of lower leg section Threaded shaft had to be straightened - used bots in pin recesses so as not to damage repaired outer flanges.

Threaded shaft had to be straightened - used bots in pin recesses so as not to damage repaired outer flanges.

Last edited: