stanzuray

Member

- 94

- 26

- 18

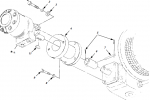

Trying to turn a nice (5000+ miles) M35A3C with winch into a dependable search and rescue vehicle for our winter ice road into the village.

Working on the winch now which I was told did work but does not now. Downloaded some TM's and got two more coming from eBay but could use someone to help me trouble shoot it. Hydraulic fluid looks good. Levers lock drum forward and reverse. Follow the operating sequence and get no sounds or movements. Any things to look for and check out would be appreciated. Was last run by people who should not have been using the winch is probably the issue. What could they have broken. Thanks Stan

Working on the winch now which I was told did work but does not now. Downloaded some TM's and got two more coming from eBay but could use someone to help me trouble shoot it. Hydraulic fluid looks good. Levers lock drum forward and reverse. Follow the operating sequence and get no sounds or movements. Any things to look for and check out would be appreciated. Was last run by people who should not have been using the winch is probably the issue. What could they have broken. Thanks Stan