Jones

Well-known member

- 2,237

- 83

- 48

- Location

- Sacramento, California

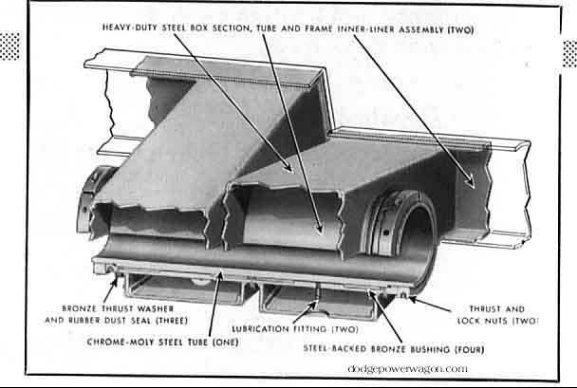

When I was in 'Nam we had two M37s that had flex joints in the frames allowing the front end of the truck to rotate, along it's axis, from the rear. The set-up consisted of a double crossmember with a big slip joint made out of two pieces of pipe; an inner, attached to the forward x-member and the outer attached to the rearward one. The pipe joint was lubricated with grease fittings and had a collar that kept the thing from pulling apart. The whole set-up was large enough and positioned so that the rear driveshaft ran through the hole. Flex lines in horseshoe shape allowed fuel and rear brake circuits to work. The whole thing could be locked solid by sliding pins; or the pins retracted and the flex joint allowed to do it's thing. I never new if these were motor pool mods or something that Chrysler was experimenting with as a way to extend the life and versitility of the M37s as an answer to the Gama Goats. Both set-up were identical and pretty professional looking. The reason for the validity of the Chrysler experiment argument is that it was right about the time of the Chrysler Screw Amphibian and a forward control 5/4 ton truck built on the M37 Weapons Carrier idea.

Does this ring a bell with anybody?

Does this ring a bell with anybody?