KLChurch

New member

- 475

- 2

- 0

- Location

- Montgomery/TX

During the mid 70's to the bottom 90's Analogue controlled metal cutting machines (NC) were more accurate than the CNC machines.

This is because CNC machines had CPU's that had a speed of approx 4 Mega HZ . 8086 chips. Today the chips they use are 1.8 to 4.9 giga hz. Now the digital (CNC) can machine accurately equal to the analogue machines.

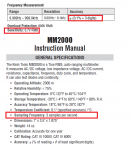

So how fast are the DMM are sampling? Depends on the CPU. The faster it samples and displays will give you the high and low peaks.

4 mega hz cnc machines sampled every 20 to 30 milliseconds. With this speed it was difficult to hold plus or minus .005 inch where the nc machines could hold plus or minus .001 inch

This is my two cents.

Kris

This is because CNC machines had CPU's that had a speed of approx 4 Mega HZ . 8086 chips. Today the chips they use are 1.8 to 4.9 giga hz. Now the digital (CNC) can machine accurately equal to the analogue machines.

So how fast are the DMM are sampling? Depends on the CPU. The faster it samples and displays will give you the high and low peaks.

4 mega hz cnc machines sampled every 20 to 30 milliseconds. With this speed it was difficult to hold plus or minus .005 inch where the nc machines could hold plus or minus .001 inch

This is my two cents.

Kris

Last edited: