- 4,047

- 6,791

- 113

- Location

- MA

Anything Lister related, reach out to Gary Jones @ Diesel Electric Services. If its Lister, he can help you.

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

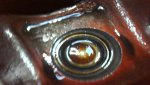

Yes it should move but you need to make sure you do a full rotation of the motor to see it turn. From your video of start up and stop, it looks good. Have you pop tested the injectors? I know you said you checked them and cleaned but how did you check them?I removed the 4th cylinder IP and checked its thrust cup and the one for the third cylinder. I turned the crankshaft from the radiator fan and the thrust cups didn't move a bit.

View attachment 804141

I was afraid to dead crank it in case something can fly out since the IP is not in place. Should the thrust cups move by just turning the crankshaft? If so, these are stuck... what's the best way of free them?

I’m in Sebastian Florida, just purchase a low hour (100) MEP803A, would like to contact you on your experiences & incite on your generator. How can we connect?Thank you for confirming!