The_DJ_Remixer

Member

- 49

- 24

- 8

- Location

- SW Pennsylvania

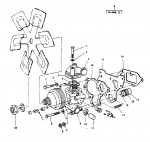

Good morning everyone, I hope your day is going good. I picked up a 803a for a fair price, and I'm servicing it in preparation to install for my home backup. Water pump (or that O ring at the bottom) was leaking pretty good. I ordered a water pump, found a video or two on youtube and will be installing it this week. Any tips/tricks I should know about before installation? Seems to be a fairly easy job. One question I had for anyone who's done the job... did you use any rtv or other on the pump gasket or thermostat gasket? I noticed the backing plate does not have a gasket available, so I'll use some fel-pro blue make a gasket material. Obviously I don't want it to leak, so RTV (or similar) or no?

I read up on the fuel gauge being sensitive on these machines. Mines pegged all the way to the left (below E). Read up that in most cases if its to the left, its either stuck or the sending unit is stuck or faulty, or perhaps wiring. Since I'm going to do the water pump job, I'd like to address the fuel gauge as well. I was reading up on threads here, but didn't get the exact answer I was looking for. If I were to replace the sending unit, I seen some folks using a 5.5 inch universal kit, but it leaves the gauge about a 1/4 tank off, so they say. These threads were a few years older. It seems that there are a lot more options in regards to sending unit length available now. Since I don't have the sending unit disconnected yet, wouldn't it be better to get a 6.5 or even 7.5 (if 8.5 is OEM?) length? I want to do this job once and be done with it. Some folks say that the 8.5 could rub and get caught up on the edge of the tank.

Finally, thank you all for your time. It's really nice to have an old school forum still active and moreso for these military machines. Take care and best to you!

I read up on the fuel gauge being sensitive on these machines. Mines pegged all the way to the left (below E). Read up that in most cases if its to the left, its either stuck or the sending unit is stuck or faulty, or perhaps wiring. Since I'm going to do the water pump job, I'd like to address the fuel gauge as well. I was reading up on threads here, but didn't get the exact answer I was looking for. If I were to replace the sending unit, I seen some folks using a 5.5 inch universal kit, but it leaves the gauge about a 1/4 tank off, so they say. These threads were a few years older. It seems that there are a lot more options in regards to sending unit length available now. Since I don't have the sending unit disconnected yet, wouldn't it be better to get a 6.5 or even 7.5 (if 8.5 is OEM?) length? I want to do this job once and be done with it. Some folks say that the 8.5 could rub and get caught up on the edge of the tank.

Finally, thank you all for your time. It's really nice to have an old school forum still active and moreso for these military machines. Take care and best to you!

Attachments

-

2.3 MB Views: 6