DieselGenAC

New member

- 53

- 2

- 0

- Location

- NJ

Yes, that is from the 2kW TM.This is from the TM for the 531A/501A units? The TM for the MEP-831A is 0033. Has basically no information. Says basically that if it's broken, replace it.

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Yes, that is from the 2kW TM.This is from the TM for the 531A/501A units? The TM for the MEP-831A is 0033. Has basically no information. Says basically that if it's broken, replace it.

Fantastic information. Tomorrow, I will check mine against these.Colt,

I took some mechanical measurement's today on one of my 831's for you to compare your actuator and mechanical governor to.

Measurements are shown below as measurement "A" and "B".

"A" is the gap between the magnet and the target on the actuator arm as measured at the top of the two surfaces.

"B" is the distance from the black throttle arm and the bottom edge of the top of the mechanical governor plate.

See pic below for locations of distances "A" and "B".

Click picture below to zoom in.

View attachment 775965

In all conditions below the round ball nut on the actuator rod is firmly seated in the black throttle arm socket.

Condition 1: Generator off and target contacting magnet.

Distance A = 0.00"

Distance B = 4.100"

Condition 2: Generator off and actuator "pinned" for a manual start. Spring loaded pin in holding actuator in near WOT position for a manual start.

Distance A = 1.00"

Distance B = 3.52"

Condition 3: Holding the actuator as far away from the magnet as possible.

Distance A = 1.265"

Distance B = 3.360"

HTH!

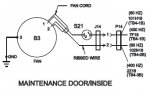

The airflow direction is OUT of the cabinet.... Can someone by chance look at their wires & tell me what wires with the numbers on them (101H18 & 102N1go to what pin on the fan & temperature switch? And also, what direction the airflow is?

View attachment 776408

J14 that Colt needs is a Molex 0003092022. $0.23Part number for P14 is 03-09-1022. NSN: 5935-01-012-1273 . You need the other side.

This is a MOLEX plug. Should be easy to find both the male and female sides of the plug.

LED bulb came in today & it works! It also works in my 802A. Here is a link in case anyone else needs one. They have multiple colors.

https://www.aero-lites.com/product-...t-drop-in-led-replacement-for-ge-327-24-28vdc

Where does a bulb work on an 831?

It is for the circuit interrupter indicator light.LED bulb came in today & it works! It also works in my 802A. Here is a link in case anyone else needs one. They have multiple colors.

https://www.aero-lites.com/product-...t-drop-in-led-replacement-for-ge-327-24-28vdc

Where does a bulb work on an 831?

10 gauge all the way. I'm not sure if the meter I have is fast but it does have a clamp on ammeter that I could put around the Romex to watch for amperage spike. Also could put the pins in the plug when it's starting.What is the wire size between the generator and loads? If you are running in 115v mode you'll need at least #10.

If you have a pretty fast volt meter with a high/low capture feature you can capture the voltage range at the AC unit and at the generator during a compressor start and see if you have too much voltage drop across the wire.

The 831 has decent short term surge capacity (milliseconds) but not a lot of generation overhead otherwise.

I though about this too. I had a 25ft cable going into the main breaker, then maybe, another 20ft of wiring in the cabin to the units.Lets not forget cable length. I would assume, and you all know how I feel about that! But assume your cable is fairly short. But if not, that can affect it also.