Hey Guys, just bought two trailer mounted MEP002's with ASK enclosures. Both appear to be in excellent condition. One I've started on shows 410 hours. Model year 1991. Fuel tank was about 3/4 full and smelled stale but not too gummy. Oil looked new and overfilled - an oddity later explained by the dry oil filter canister with new filter. Apparently changed oil but didn't run it in.

I did all the customary preps to try and start: flushed & refilled fuel tank w/ fresh diesel incl some diesel Kleen additive, removed & cleaned both fuel pumps. First one was pretty dirty with rusty brown debris. Second pump pretty clean. Fuel strainer looked clean with just a little varnish on canister. Changed fuel filters, purged air at secondary filter housing top then cracked fuel line at injector pump inlet and primed. Fuel came out at IP inlet and seems to be recirculating to fuel tank.

Added couple new batteries and gave it a try. Cranks like a champ but won't start. Glow plugs are working nicely (ouch) but won't fire and no white smoke. Cracked line from IP to injector - no fuel coming through IP. At time didn't know to check the control lever for binding. But, it was not free and not rising when fuel shutoff solenoid energized. It was not locked completely and I spent some time semi-gently working back and forth until it eventually became free. But, still no fuel coming out of IP.

I'm assuming I need to pull the pump as the plunger or something(s) are frozen up. Guy at base said they'd been there about 4 years if that helps. I'm nervous about tearing into it as I have no experience with IPs so have read all of this as well as other posts and downloaded the TMs and read. But, before I pull it I have a few questions I'm hoping y'all can answer:

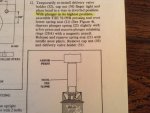

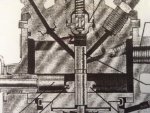

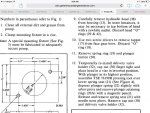

1) any chance I can free it up without pulling? I cranked it a lot. Is it a certainty that something is broken (like the guide)? Should I try soaking it through ports with something like WD40 or Kroil. If so, which ports would get it where it needs to be? If plunger is stuck out (away from cam lobe) could it be tapped in through the fuel delivery valve assembly hole and possibly freed up?

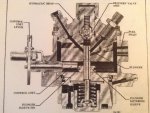

2) I've looked at several TMs and exploded diagrams but have never seen the black metal plunger guide that you guys have shown broken. Is the pump different than that shown in TMs? Also, the links to AMBAC above from 2013 don't work now.

3) if I find broken parts are they still available from AMBAC?

4) I'm more worried about messing up timing than the pump. If I clean, repair and replace the same pump with same shim, etc and put back on without moving engine crank will it go back on indexed as it came off? I don't really understand the 1/8" drill bit in the timing screw hole step as far as what it's doing as regards timing to extent that is most likely NOT where it was when removed from engine? Is there anything I could or need to do or mark on the driven gear teeth to help in reinstallation without affecting timing?

Thanks in advance for any help or advice you guys can give.

Ross

it came right out. AMBAC says the parts should go out tomorrow.

it came right out. AMBAC says the parts should go out tomorrow.