- 282

- 508

- 93

- Location

- Indianapolis, Indiana

As I mentioned in my new member introduction thread, my first military vehicle was my M109A3. Mid way through the rust repair on the van body itself, which was desperately needed prior to my intended camper conversion, I purchased an M923A2 from GovLiquidation and changed my plans a bit. I decided to put the van body on the 5 ton chassis and use that resultant combination as my camper truck. So with that background, here's what I have done so far.

My work started with addressing a couple leaks in the roof. I thought that once I stopped those, then the rest of the problems would be minor. I was sealing up a small leak in one of the window frames during a light rain shower (It helped me find out what was actually leaking) when I felt just the slightest creak under one of the oak floor boards. Thinking I probably had a little rust under one of the boards, I took up a couple boards in the front driver's side corner and found that the metal pan beneath the floor was completely rusted through. The floor pan of these trucks holds in absolutely every single drop of water that gets in and doesn't evaporate. So, with a couple boards ripped up, there was no going back. This was also 2 weeks before I had intended to take the truck on a camping trip.

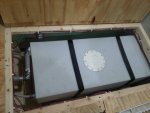

Thanks to some help from a good friend, I was able to make the camping trip in a truck with a brand new plywood floor, with a completely new 14 gauge metal pan beneath it. I've never hated spot welds more in my entire life. I've also never seen so much loose rust at once, either - I swept up 8 gallons of it underneath the old oak flooring! Thankfully, the structure beneath the floor pan was intact so that was as far down as I had to go.

At this point I wasn't taking many pictures because I had a lot to do and not much time! I primed and painted the sheet metal before redoing the spot welds at the edges and installing a new plywood floor where the oak had been.

My work started with addressing a couple leaks in the roof. I thought that once I stopped those, then the rest of the problems would be minor. I was sealing up a small leak in one of the window frames during a light rain shower (It helped me find out what was actually leaking) when I felt just the slightest creak under one of the oak floor boards. Thinking I probably had a little rust under one of the boards, I took up a couple boards in the front driver's side corner and found that the metal pan beneath the floor was completely rusted through. The floor pan of these trucks holds in absolutely every single drop of water that gets in and doesn't evaporate. So, with a couple boards ripped up, there was no going back. This was also 2 weeks before I had intended to take the truck on a camping trip.

Thanks to some help from a good friend, I was able to make the camping trip in a truck with a brand new plywood floor, with a completely new 14 gauge metal pan beneath it. I've never hated spot welds more in my entire life. I've also never seen so much loose rust at once, either - I swept up 8 gallons of it underneath the old oak flooring! Thankfully, the structure beneath the floor pan was intact so that was as far down as I had to go.

At this point I wasn't taking many pictures because I had a lot to do and not much time! I primed and painted the sheet metal before redoing the spot welds at the edges and installing a new plywood floor where the oak had been.