- 2,113

- 563

- 113

- Location

- Davis County, UT

What Monroe shock number did you order/use Jeepsinker? I used the 66605, and I had zero problems with the bushings. The shocks fit perfectly in every way.Note: the new bushings that come with the Monroe shocks will not fit unless you grind them down some. They are too thick.

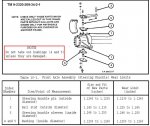

Each shock came with 2 baggies of the following:

Note 1: I did not need the metal shaft spacer, as the shock mounts on the deuce were already appropriately narrow

Note 2: The rubber bushings are identical, I'm just illustrating what both sides look like

On either side of the deuce shock mounts, there is a raised lip, the bushing's nipple fit great inside this raised lip.

The only real item of note was the bottom shock mount, as the mount support is a tad close (the bushing is pressed right against it), but in my opinion, it's fine.

Top mount also was fine:

And I changed my other mind and painted shocks black:

WORD OF NOTE:

I found it beneficial that I had NOT cut these shock straps when I first pulled the Monroe's from their packaging (they're just to keep the shocks compressed for more efficient shipping). Again, because I'm not Superman I found it much more difficult to attempt to compress the shocks on the truck, and much easier just putting one end on the cement in front of me.

What I did was loop one end of the plastic retainers on the bottom of the shock like normal (like how they came shipped), and then placed the other end at the TOP of the bolt. It was a bit difficult to hold the plastic strap there (it wanted to slip off), but it kept the shock compressed enough I could get it into place. Then I just cut the bottom end free.