sangamon

New member

- 49

- 0

- 0

- Location

- Seattle / Blaine

So I finally got my insurance foolishness taken care of. I took the M656 out for a quick drive around the block (about five miles) this morning.

I know I keep going on about it, but it really rides smoothly. I had warmed up my Unimog 416.163 on the same path, and I could feel every bump and pothole. I didn't feel a thing on the M656.

The nice, long, flat sides make it easy to figure out where you are on the road.

The automatic transmission shifts very nicely, and shifts when it should. It's the first automatic that I actually like.

The temperature this morning was 23 degrees. The engine started in about five seconds. That seems pretty good to me for a fourty year old engine.

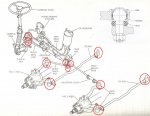

The steering is still a little stiff, and the low temperature probably didn't help. I'll do Bjorn's boiled joints treatment to take care of that.

It's a great truck.

The Border Patrol sees me in my Unimog firetruck all the time. Hopefully they won't be too surprised when I drive by in the M656.

The pictures are of the M656 in my yard - there wasn't a convenient place to get out on the road.

I know I keep going on about it, but it really rides smoothly. I had warmed up my Unimog 416.163 on the same path, and I could feel every bump and pothole. I didn't feel a thing on the M656.

The nice, long, flat sides make it easy to figure out where you are on the road.

The automatic transmission shifts very nicely, and shifts when it should. It's the first automatic that I actually like.

The temperature this morning was 23 degrees. The engine started in about five seconds. That seems pretty good to me for a fourty year old engine.

The steering is still a little stiff, and the low temperature probably didn't help. I'll do Bjorn's boiled joints treatment to take care of that.

It's a great truck.

The Border Patrol sees me in my Unimog firetruck all the time. Hopefully they won't be too surprised when I drive by in the M656.

The pictures are of the M656 in my yard - there wasn't a convenient place to get out on the road.

Attachments

-

100.1 KB Views: 169

-

99.3 KB Views: 164

-

99.1 KB Views: 159