Blood_of_Tyrants

Active member

- 1,614

- 11

- 38

- Location

- Lebanon, TN

I am in the process of tearing down a F series engine and have a few questions.

First according to the specs, the bore is 3.125" and when I measure the bore it is indeed 3.125" and there is practically no ridge. Should come out with a little honing. But something doesn't quite pan out. The pistons all have 0.020 stamped into them. I assume that 0.020 means that the the bore and pistons are 0.020" oversized. Shouldn't the bore and pistons measure close to 3.145"?

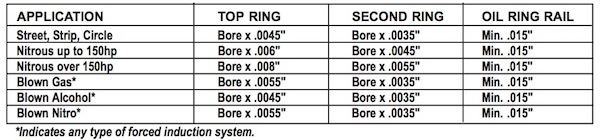

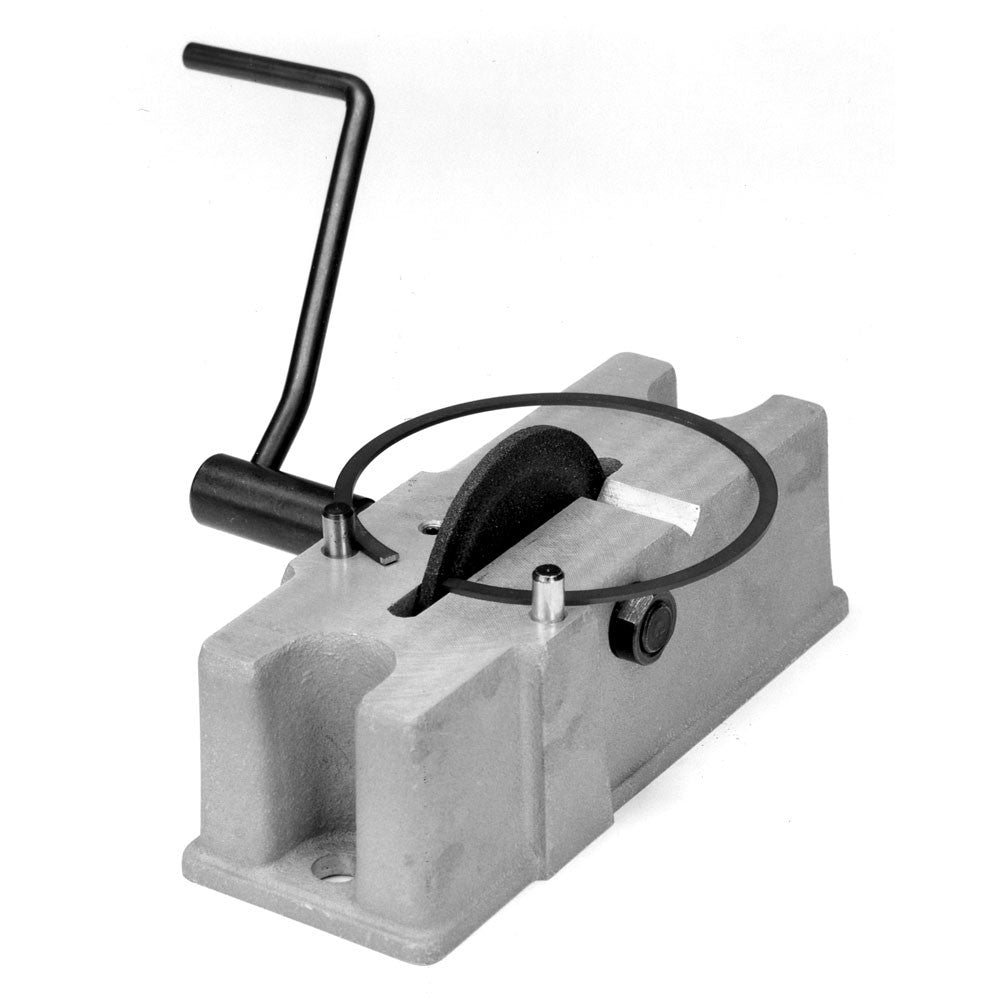

Second the end gap on the old compression rings is HUGE. Like 0.030" or bigger huge. And, yes, I used the piston to push it down a little to make sure it was square. Isn't that way too much? The manual says the end gap should be 0,008". What size piston rings should I get? I guess I could try the 0.020 oversized and hope the end gap can be ground to fit with a Dremel.

Third, what is a good source for rings? I found them at JC Whitney. And the gasket set is available from OReillys.

First according to the specs, the bore is 3.125" and when I measure the bore it is indeed 3.125" and there is practically no ridge. Should come out with a little honing. But something doesn't quite pan out. The pistons all have 0.020 stamped into them. I assume that 0.020 means that the the bore and pistons are 0.020" oversized. Shouldn't the bore and pistons measure close to 3.145"?

Second the end gap on the old compression rings is HUGE. Like 0.030" or bigger huge. And, yes, I used the piston to push it down a little to make sure it was square. Isn't that way too much? The manual says the end gap should be 0,008". What size piston rings should I get? I guess I could try the 0.020 oversized and hope the end gap can be ground to fit with a Dremel.

Third, what is a good source for rings? I found them at JC Whitney. And the gasket set is available from OReillys.