-

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Picked up 6 MEP-802A gensets and will be documenting making them all runners here

- Thread starter pclausen

- Start date

More options

Who Replied?That makes perfect sense Guy. I just assumed that since it was a 22 year old set with 32 hours on it, it would have been reset, But like you said, it could have been deployed with a unit that never used it. Unlike all my other sets, this one didn't have any shipping labels on it indicating it had been deployed somewhere in the middle East either.Yep, A1 had failed in a matter that did not take the quad windings with it, or it was swapped out at some point as Guy pointed out. Interesting that this set only has 32 hours on it, is a 2000 model, and was never reset.

There is a Reset document in the TM forum. But you need to understand what Reset is. Reset is to take older, or much used gen sets and return them to Tip, Top shape. What we called 10/20 Standards. A gen set is only supposed to be sent to Reset when id had a certain amount of hours, and other criteria. Red the reset document if you really want to know.

One reason it never hit reset is that it never got issued. Or was issued to a unit that never needed it. Could also have been reset back in the day. Back in the early days, the reset tag was a plastic POC that was simply pasted on the side of the gen set. You all place way too much emphasis, (Hope) on Reset. At times it was less then spotty. At times, super. But what all of you fail to understand, or better said, Know, is that Reset was more or less a guideline. At first anyway. After 2010, when I stopped contracting, I can not speak with knowledge. But it was a guideline. Some things listed in the Reset document were to be done on a, AS NEED BE basis. "If it aint broke, it dont get fixed". Often, if a part was supposed to be changed, say the TTM, (Time Totaling Meter), and the supply system did not have them, or was not able to supply them in time, the set was kicked out of shop. It was recorded as finished, with the following exceptions. And a list was provided. That list promptly went into the trash can. Who cares? works? Great. End of story. Reset is not the Holy Grail.

Also, when I drained the fuel, I pulled the strainer, which looked like this:

It had that growth on both the outside and inside. It scraped off easily on the outside with a plastic edge. I plan to power wash it (carefully) to get rid of growth on the inside and the strainer itself. I see changing those 2015 fuel filters in my near future! Would probably not hurt to pull the tank and give it a thorough cleaning as well.

That growth could be the result of sitting unused for a LONG time with the original fuel from 2000 in it I suppose.

- 4,042

- 6,775

- 113

- Location

- MA

I picked up a Kubota L3560 this past year, and its a real nice tractor. It has the bigger frame and running gear of the Grand L family, but 35HP and a great all around performer. Its a great compromise to me... larger, heavier footprint, with better fuel economy. I don't do a ton of ground engagement (I do have a 72" PTO tiller that it spins with ease), so the tradeoff in fuel consumption is great. It will easily lift an 803A to 6+ feet. The tires are full, and I've got a quick attach on the back with a heavy hitch and ~600lbs in counterweight at all times. The 48" skid steer forks are great too. Photo is from the dealer the day I made the deal.Nice! I’m looking at either a 2038r or a 3039r. Right now I have a 4200 but I need a loader and haven’t been able to fine one to fit it.

- 4,042

- 6,775

- 113

- Location

- MA

Very nice! Like your counterweight setup. That 3 point quick hitch is nice too. Really like the adjustable height center point. I looked at those for my big tractor (cat 2) but they were all fixed height of about 15" or so and my implements are all over the place.

I'll see your 802A and raise you a Saab:

If I didn't already have the 5 series, I would have probably looked for something with more lift capacity than what the little 1 series can provide. But I specifically wanted something small for mowing grass and doing stuff around the house, as well as trench in tight places. It fits the bill nicely for that.

I was looking around for a loader for my little Ford 1700 for the longest time, but finally have up and just got the 1 series. Deere dealer had taken the 1700 in on trade and my sales guy cut me a hell of a deal and let me have it for $2,500. She was rough when I first got her:

But after some sandblasting and fresh paint, she shined right up:

Only had 390 hours on it too:

Those little Fords CUTs were made in Japan. Maybe they still are?

I mainly use it to mow my lower field:

And of course moving the 803 around:

Once I get all these 802's going, I'll turn my attention to the 803. Haven't even had a chance to fire it up since bringing it home last month as I want to look it over really well before doing so. It did start and make power the day I picked it up from a guy in Pittsburg. I swear is seemed quieter than a 802 when we tested it. I'm sure 4 cylinders help and it also had foam inserts in the air baffle intakes. I guess all 802/803s did when new, but none of my 802s still have them. Some have a foam pad under the engine, but that's it as far as sound deadening material.

I'll see your 802A and raise you a Saab:

If I didn't already have the 5 series, I would have probably looked for something with more lift capacity than what the little 1 series can provide. But I specifically wanted something small for mowing grass and doing stuff around the house, as well as trench in tight places. It fits the bill nicely for that.

I was looking around for a loader for my little Ford 1700 for the longest time, but finally have up and just got the 1 series. Deere dealer had taken the 1700 in on trade and my sales guy cut me a hell of a deal and let me have it for $2,500. She was rough when I first got her:

But after some sandblasting and fresh paint, she shined right up:

Only had 390 hours on it too:

Those little Fords CUTs were made in Japan. Maybe they still are?

I mainly use it to mow my lower field:

And of course moving the 803 around:

Once I get all these 802's going, I'll turn my attention to the 803. Haven't even had a chance to fire it up since bringing it home last month as I want to look it over really well before doing so. It did start and make power the day I picked it up from a guy in Pittsburg. I swear is seemed quieter than a 802 when we tested it. I'm sure 4 cylinders help and it also had foam inserts in the air baffle intakes. I guess all 802/803s did when new, but none of my 802s still have them. Some have a foam pad under the engine, but that's it as far as sound deadening material.

Last edited:

- 4,042

- 6,775

- 113

- Location

- MA

I was waiting months for a smaller L (3901) to come in to stock, and my local dealer called me and informed me that a cash buyer had backed out and that this Grand L base model was available... I had no idea they had this particular model in the lineup. The price was right, and so was the financing (0 for 84)... just works out some time. You have a nice fleet of machines.

The 803s are quieter to me. If I needed the power I would have one, not my 802.

The 803s are quieter to me. If I needed the power I would have one, not my 802.

- 4,042

- 6,775

- 113

- Location

- MA

The quick hitch came from here: https://www.palletforks.com/tractor...ry-1-and-2-3-point-quick-hitch/QH1-GROUP.html)Very nice! Like your counterweight setup. That 3 point quick hitch is nice too. Really like the adjustable height center point. I looked at those for my big tractor (cat 2) but they were all fixed height of about 15" or so and my implements are all over the place.

The weights and heavy hitch from here:

Category 1 Dual Receiver Hitch and Suitcase Weight Bracket | Heavy Hitch - Compact Tractor Attachments

Upgrade your tractor with the Category 1 Dual Receiver Hitch and Suitcase Weight Bracket for 3 Point Hitch. Made in the USA, durable, and versatile.

2" Vertical to Horizontal Receiver | Heavy Hitch - Compact Tractor Attachments

Convert your vertical receiver to horizontal with the Heavy Hitch 2" Vertical to Horizontal Receiver. Easy installation and compatible with standard 2" hitches.

Tractor Suitcase Weights | Heavy Hitch - Compact Tractor Attachments

Enhance tractor stability with Heavy Hitch tractor Suitcase Weights. Perfect for adding ballast and improving performance. Made in the USA.

And a bushing set to convert my CAT1 to CAT2.

Thanks for those links! Will have to look into that Titan for sure!

So back on the 802s. I pulled the #2 IP from the 2007 that only fires on that can intermittently. Didn't really feel or see any issue with it, but swapped it for one from my spare unit. Went to put in back in and noticed this:

It looks like the push rod tube seals were reversed when I installed them. The ones with the wider shoulder goes on top and the narrow ones goes on the bottom so that the IP will clear. Wasn't a big deal during the initial assembly since the IPs when in before the head. But now that I popped one out, I can't get it back on without squeezing the seal with the shims. I guess that's what I get waiting 6 years between disassembly and re-assembly...

So time to drain the coolant (fortunately still just water), remove the front clip, water pump, manifolds and the head, to swap those seals around. Fun times!

So back on the 802s. I pulled the #2 IP from the 2007 that only fires on that can intermittently. Didn't really feel or see any issue with it, but swapped it for one from my spare unit. Went to put in back in and noticed this:

It looks like the push rod tube seals were reversed when I installed them. The ones with the wider shoulder goes on top and the narrow ones goes on the bottom so that the IP will clear. Wasn't a big deal during the initial assembly since the IPs when in before the head. But now that I popped one out, I can't get it back on without squeezing the seal with the shims. I guess that's what I get waiting 6 years between disassembly and re-assembly...

So time to drain the coolant (fortunately still just water), remove the front clip, water pump, manifolds and the head, to swap those seals around. Fun times!

I decided the "cheat" and very carefully trimmed just enough of the tube seal to allow the IP base plate to drop down against the block, being careful to catch each trimmed off piece so it didn't fall down into the block.

Turned the IP counterclockwise against the rack and snug up the clamp. Fired it up and at first I still only fired on #1, but after bleeding IP #2, the 2nd can came to life. Stopped and started a few times, and all seems well now!

Next task will be to figure out why this set is not making any power, not even with S1 in START.

Turned the IP counterclockwise against the rack and snug up the clamp. Fired it up and at first I still only fired on #1, but after bleeding IP #2, the 2nd can came to life. Stopped and started a few times, and all seems well now!

Next task will be to figure out why this set is not making any power, not even with S1 in START.

- 18,134

- 27,230

- 113

- Location

- Burgkunstadt, Germany

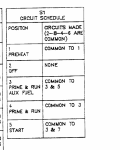

So the wires all appear to be hooked up correctly. The function of the switch also appears to be correct. I see 0.1 Ohm between the 4 common pins and 3 when in PRIME & RUN and also 7 when in START.

HOWEVER, I get 32 Ohms between any of the common pins and the GND stud on the flip down panel. I get 0.1 Ohm between the flip down GND stud and the A1 GND stud and also to GND on the slave plug.

So somewhere on the flip down panel I'm somehow getting 32 Ohms resistance. I think the next logical step would be to check all the grounds on TB 6 to get those readings.

All that said, even though I get 32 Ohms from S1 to all the grounds, the heater elements works, both main and aux pumps works, and it cranks and starts when in START position.

HOWEVER, I get 32 Ohms between any of the common pins and the GND stud on the flip down panel. I get 0.1 Ohm between the flip down GND stud and the A1 GND stud and also to GND on the slave plug.

So somewhere on the flip down panel I'm somehow getting 32 Ohms resistance. I think the next logical step would be to check all the grounds on TB 6 to get those readings.

All that said, even though I get 32 Ohms from S1 to all the grounds, the heater elements works, both main and aux pumps works, and it cranks and starts when in START position.

- 2,330

- 4,198

- 113

- Location

- Massachusetts

I'd suggest measuring the DC voltage across A1 terminals 5 & 6 with the set running and S1 in Start to see if the set is flashing the gen head.

The voltage there should be approx 7.6 volts DC.

If you get around 7.6 then the flashing circuit is working. If you get around 24 volts then there is an open in the wiring between there and the exciter.

If you get around 0 volts then there is an issue with the flashing circuit.

Based on what you measure will determine what and where to check next.

The voltage there should be approx 7.6 volts DC.

If you get around 7.6 then the flashing circuit is working. If you get around 24 volts then there is an open in the wiring between there and the exciter.

If you get around 0 volts then there is an issue with the flashing circuit.

Based on what you measure will determine what and where to check next.

- 2,330

- 4,198

- 113

- Location

- Massachusetts

OK, as you move S1 from RUN to START do you see K15 moving?

K15 was NOT moving when moving S1 from RUN to START. I swapped out K15 from my spare set, and now it is moving.

Voltage between A1 terminal 5 & 6 is now around 22 volts when holding S1 in START. So based on what you said earlier, this seems like an exciter issue?

I guess there are 2 exciters. The Stator and the rotor (Armature?)

Voltage between A1 terminal 5 & 6 is now around 22 volts when holding S1 in START. So based on what you said earlier, this seems like an exciter issue?

I guess there are 2 exciters. The Stator and the rotor (Armature?)

- 2,330

- 4,198

- 113

- Location

- Massachusetts

Ok, 22 volts indicates a continuity problem from there to the Exciter or the Exciter itself.

The power from the VR to the Exciter goes thru the P5/J5 connector. I'd suggest checking the 4 pins in those connectors for corrosion.

Then check the resistance between P5 pins 1 and 2 to verify continuity from P5 to the Exciter. IIRC it should be around 12 ohms.

The power from the VR to the Exciter goes thru the P5/J5 connector. I'd suggest checking the 4 pins in those connectors for corrosion.

Then check the resistance between P5 pins 1 and 2 to verify continuity from P5 to the Exciter. IIRC it should be around 12 ohms.

You da man Kurt! I pulled P5 and pins 1 and 2 showed open. So I popped the end bell cover what what do you know, the stator leads were loose/disconnected from the small terminal block right there at the end bell. Removed and inserted all 4 leads a few times to make sure they were all the way on. I'm now getting 12 ohms between pins 1 and 2 on P5.

I had to steal the batteries for something else, but I got a couple of these showing up tomorrow that I'll throw in there:

$145 shipped to your door at a AGM 51R seems like a good deal.

So hopefully between a bad K15 relay and loose/disconnected leads to the Exciter, I'll be making power when I fire this guy back up tomorrow.

Also looking to pick up a pair of NOCO genius chargers. Would the genius 1s be enough, or should I roll with the genius 2s?

I had to steal the batteries for something else, but I got a couple of these showing up tomorrow that I'll throw in there:

$145 shipped to your door at a AGM 51R seems like a good deal.

So hopefully between a bad K15 relay and loose/disconnected leads to the Exciter, I'll be making power when I fire this guy back up tomorrow.

Also looking to pick up a pair of NOCO genius chargers. Would the genius 1s be enough, or should I roll with the genius 2s?

- 2,330

- 4,198

- 113

- Location

- Massachusetts

The genius 1s should be fine to keep the batteries topped off between uses.

Thanks. Yeah, I guess the main difference is that the 1 only has a 30Ah capacity if it needs to charge the battery, where the 2 can handle a 40Ah. Most car batteries that I have seen aren't rated based on Ah, just CCA. Anyway, picked up a pair of 1s.

So I got the new batteries in, but the posts are way to small. The positive terminal is quite a bit smaller than "standard" and the negative is way smaller. I think maybe this battery is meant for a Prius or something?

Anyway, I was able to clopper something together with some battery posts shims from the parts store, it it is not a good long term solution, but it gets me by for now.

So with the K15 replaced and the loose wiring at the exciter fixed, I started the set and it immediately bogged down to almost stalling as soon as it came up to speed:

The set almost walked off the blocks. Got it shut down just in time.

If I unplug P5 from J5, the engine doesn't bog down, but I of course don't get any power either. I check and I get the 12 Ohms at the leads going to A1 terminals 5 and 6.

So something appears to put a tremendous load on the gen head that bogs down the engine now that the exciter issue has been sorted out.

Anyway, I was able to clopper something together with some battery posts shims from the parts store, it it is not a good long term solution, but it gets me by for now.

So with the K15 replaced and the loose wiring at the exciter fixed, I started the set and it immediately bogged down to almost stalling as soon as it came up to speed:

The set almost walked off the blocks. Got it shut down just in time.

If I unplug P5 from J5, the engine doesn't bog down, but I of course don't get any power either. I check and I get the 12 Ohms at the leads going to A1 terminals 5 and 6.

So something appears to put a tremendous load on the gen head that bogs down the engine now that the exciter issue has been sorted out.

- 114,242members

- 167,167threads

- 2,353,418posts

- 5,469online users